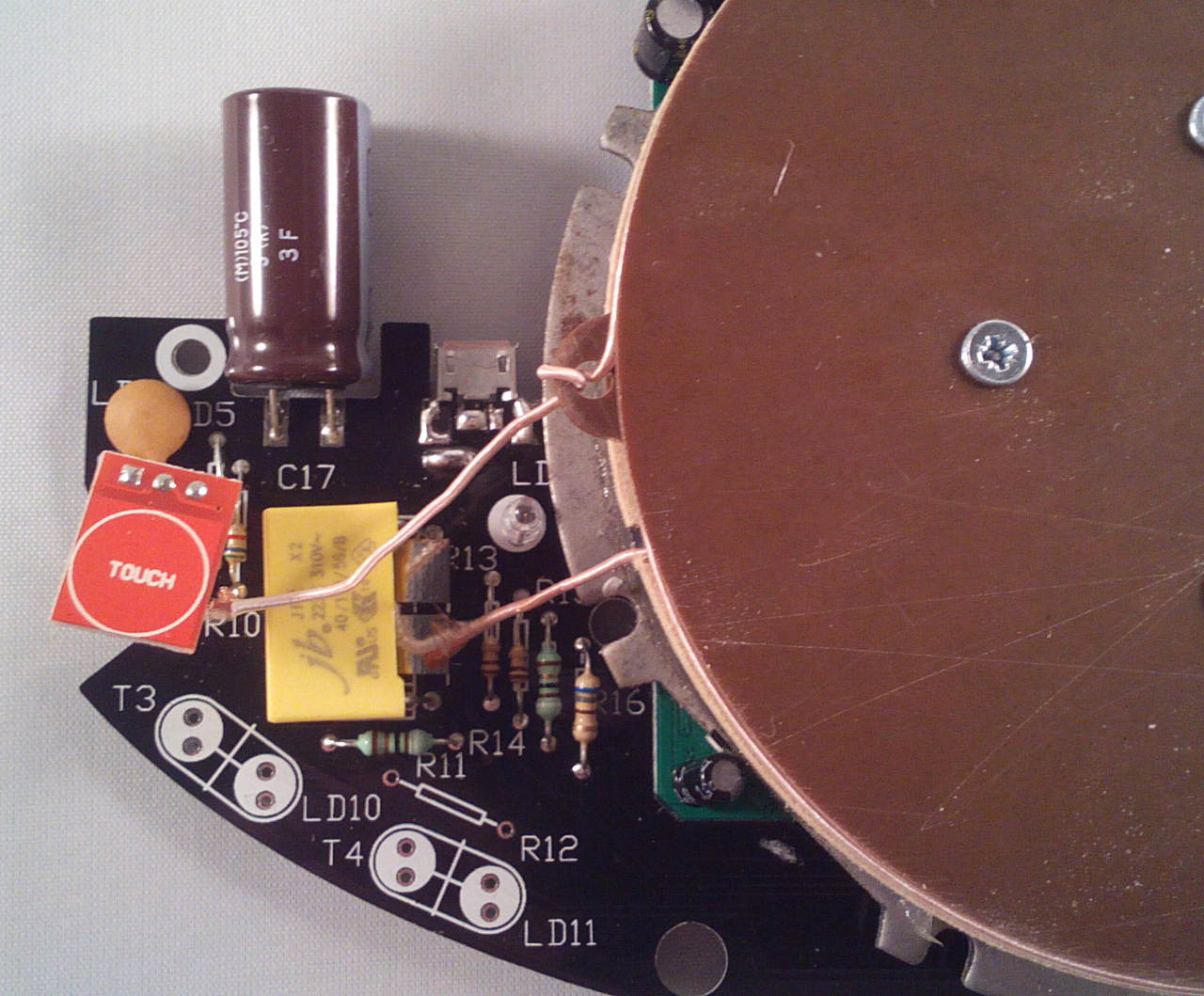

You'll need to sand the former pieces first but as they're not seen don't worry about scratching them.

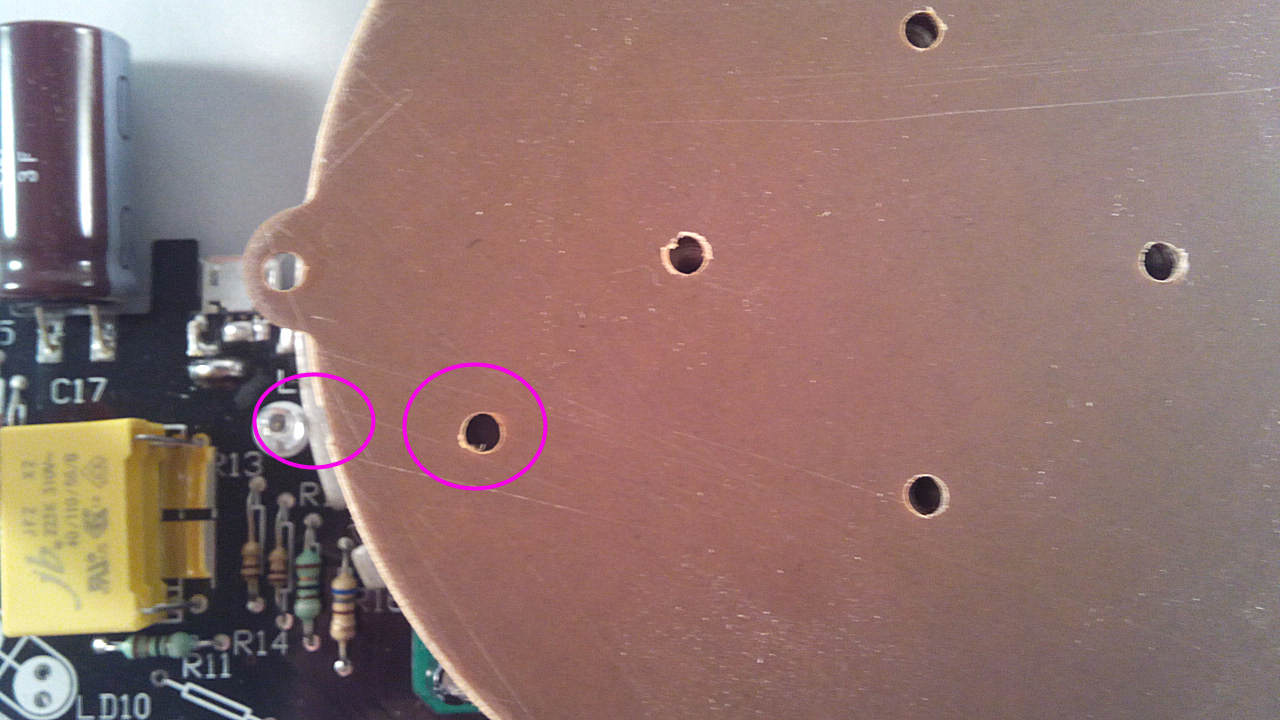

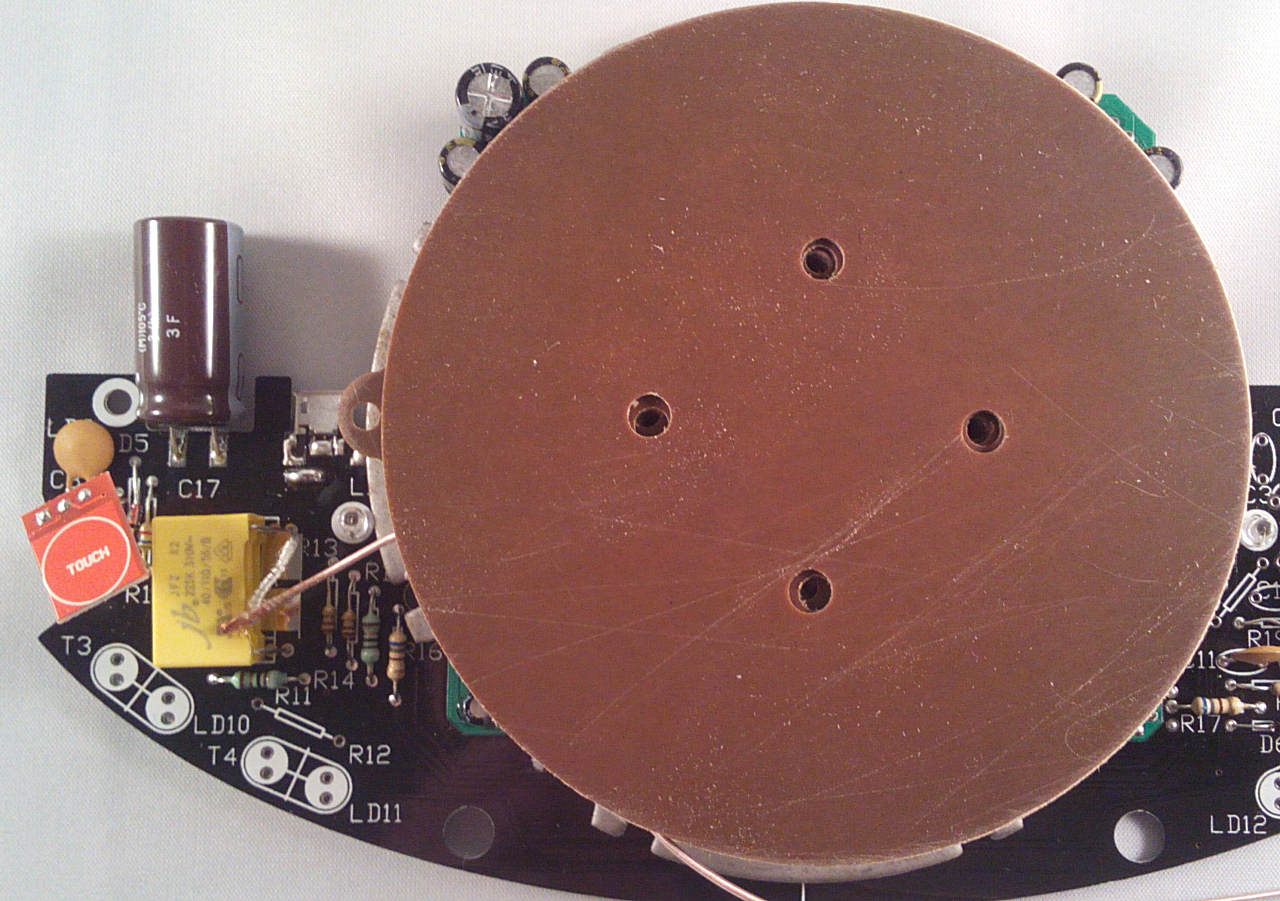

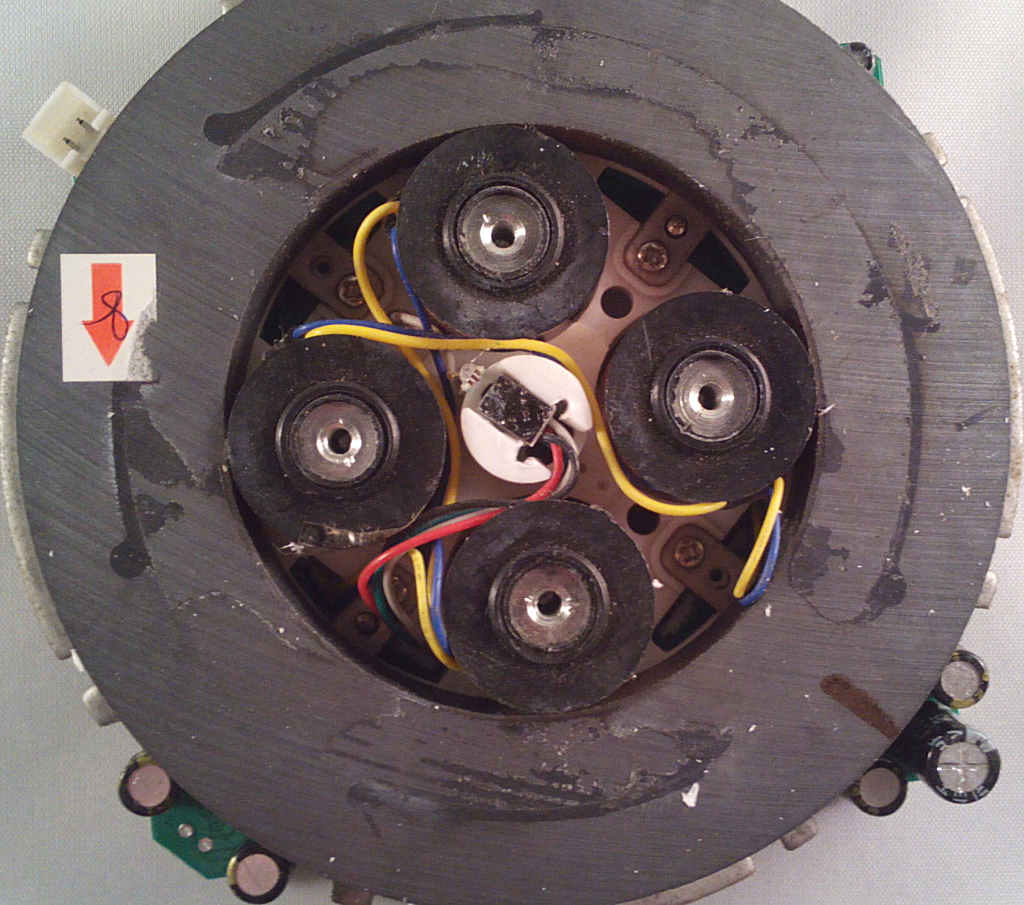

Start by removing the small magnets from the electrmagnets, if fitted:

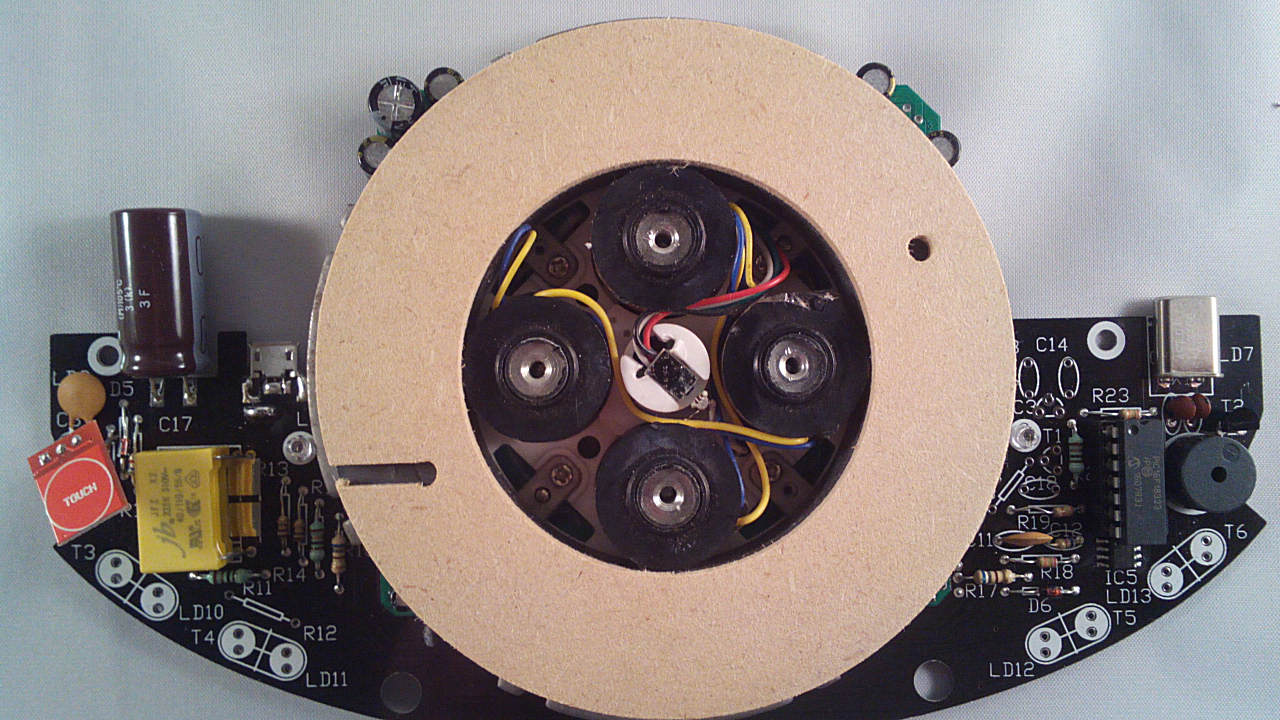

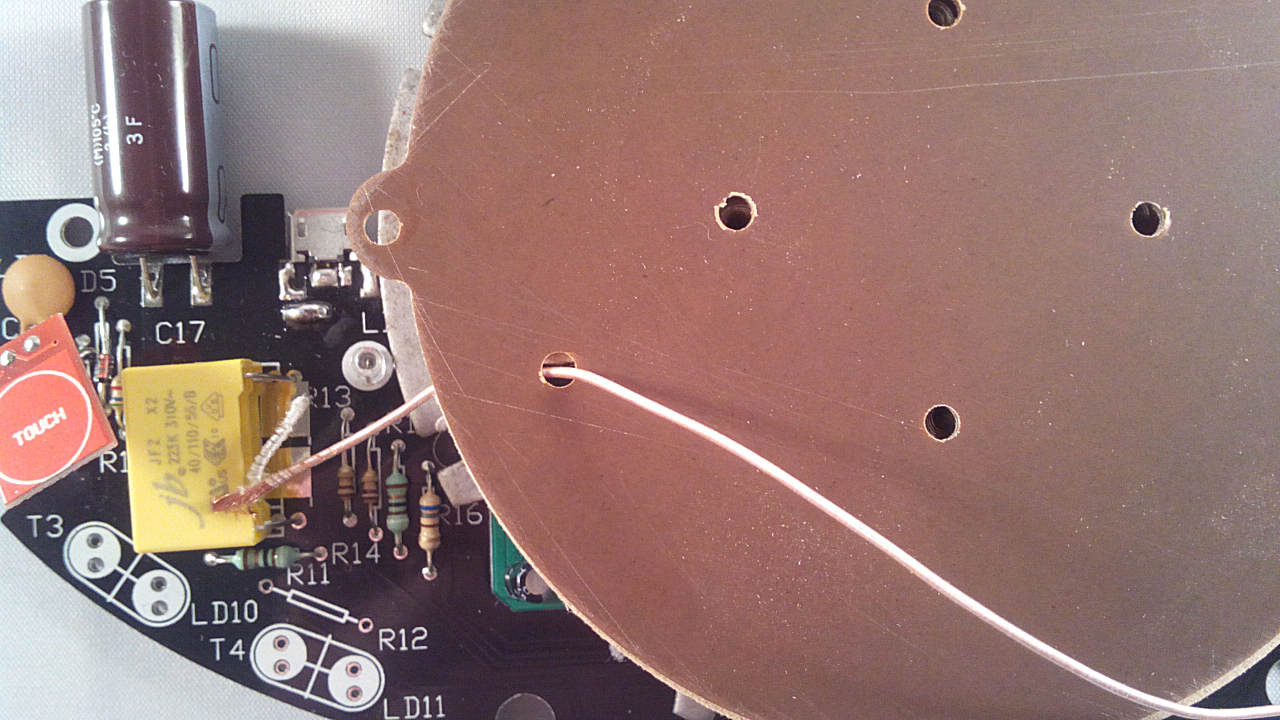

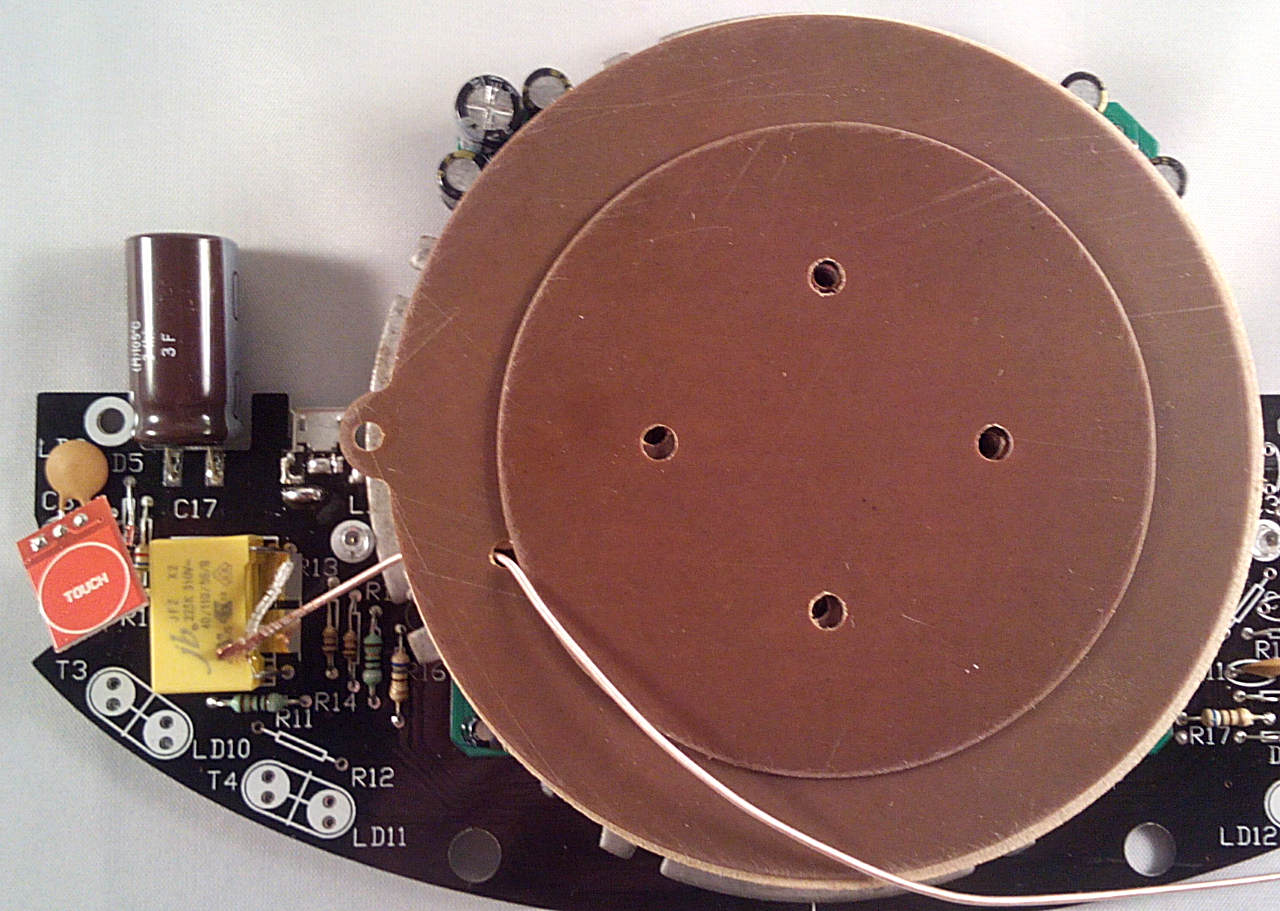

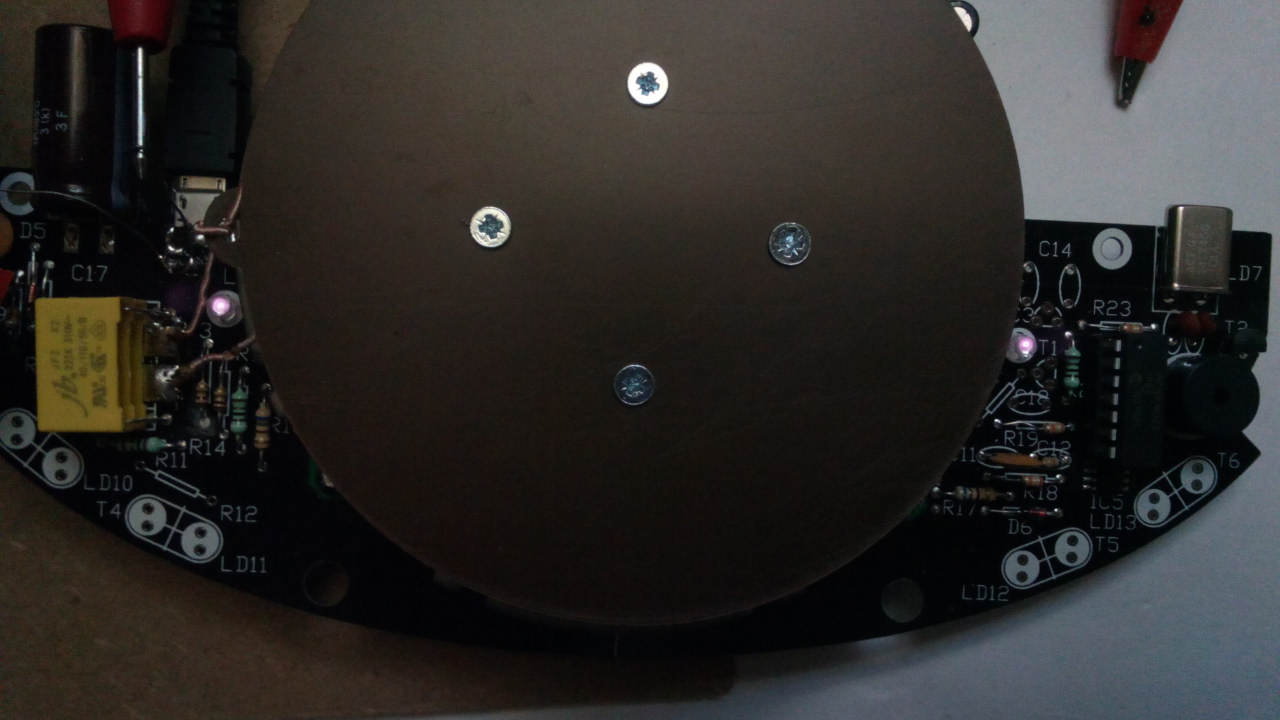

Leaving the threaded holes clear to fit the coil:

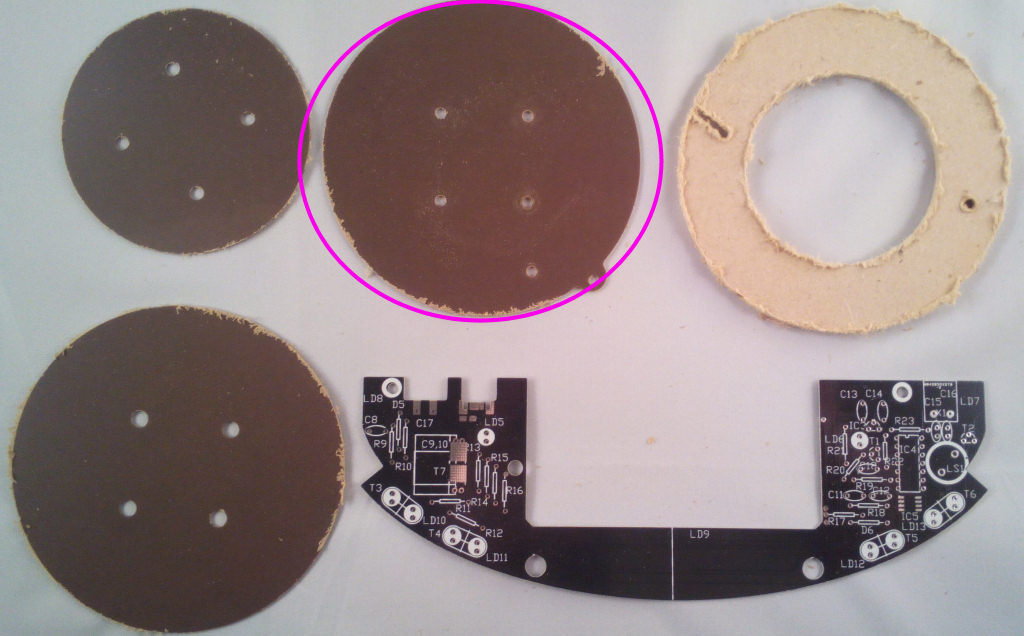

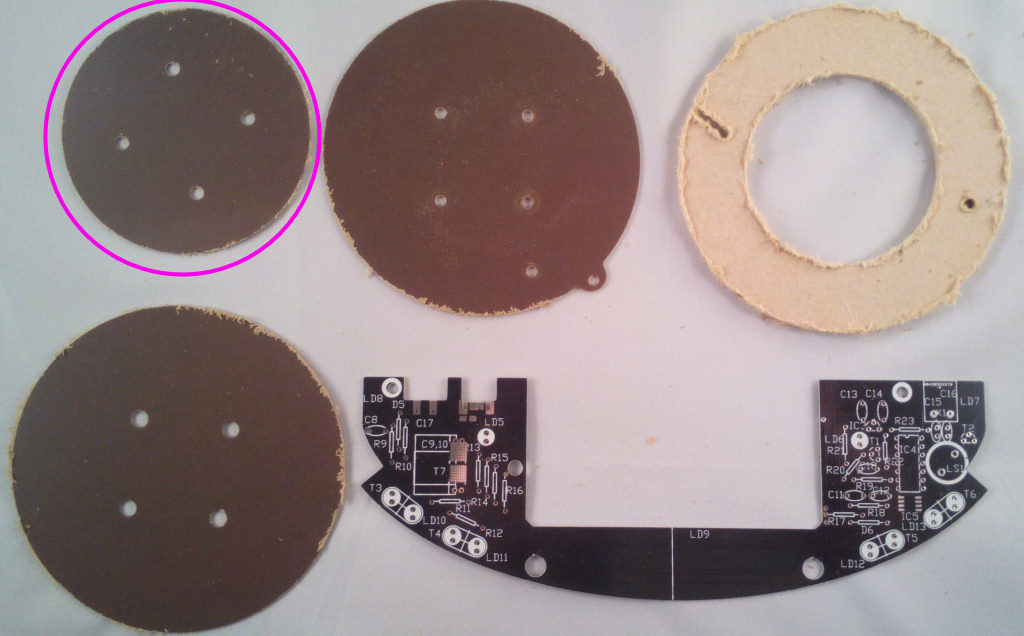

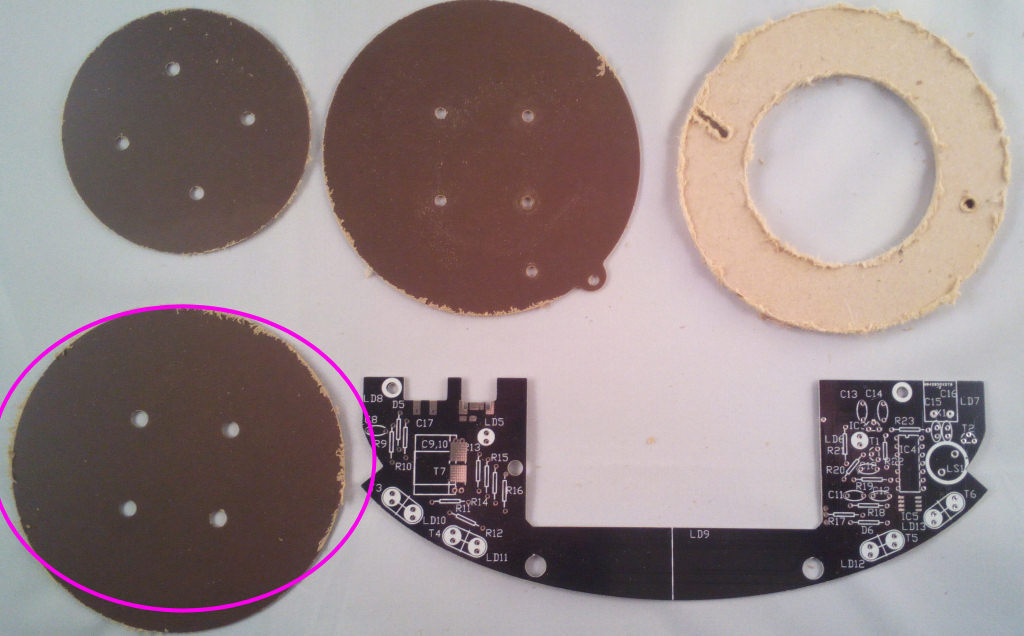

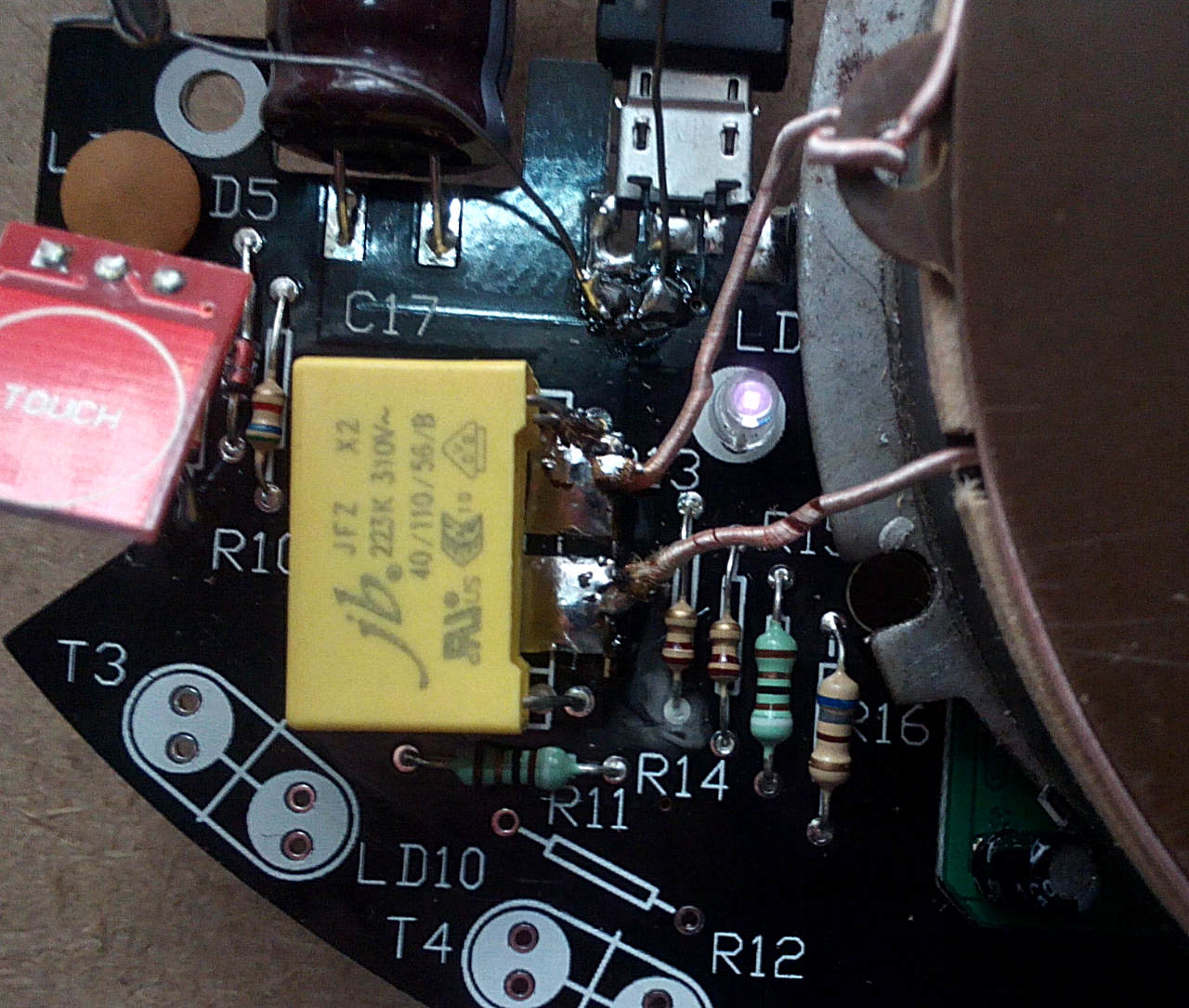

NOTE I have been helpfully sent one box of bases which didn't have these drilled but look the same until the magnets are removed. If you've been sent one of these please do the following.

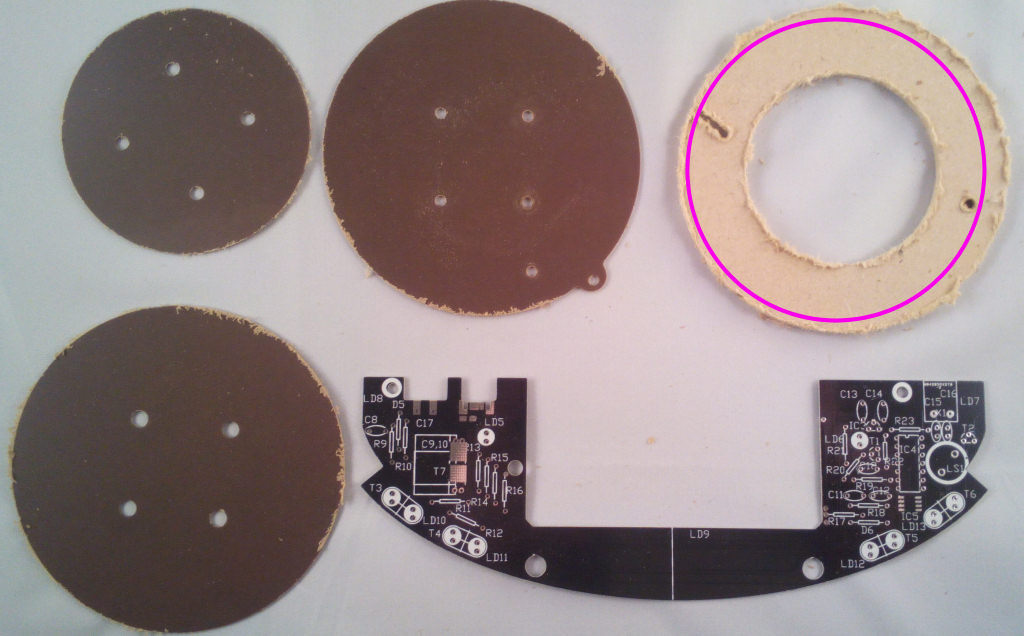

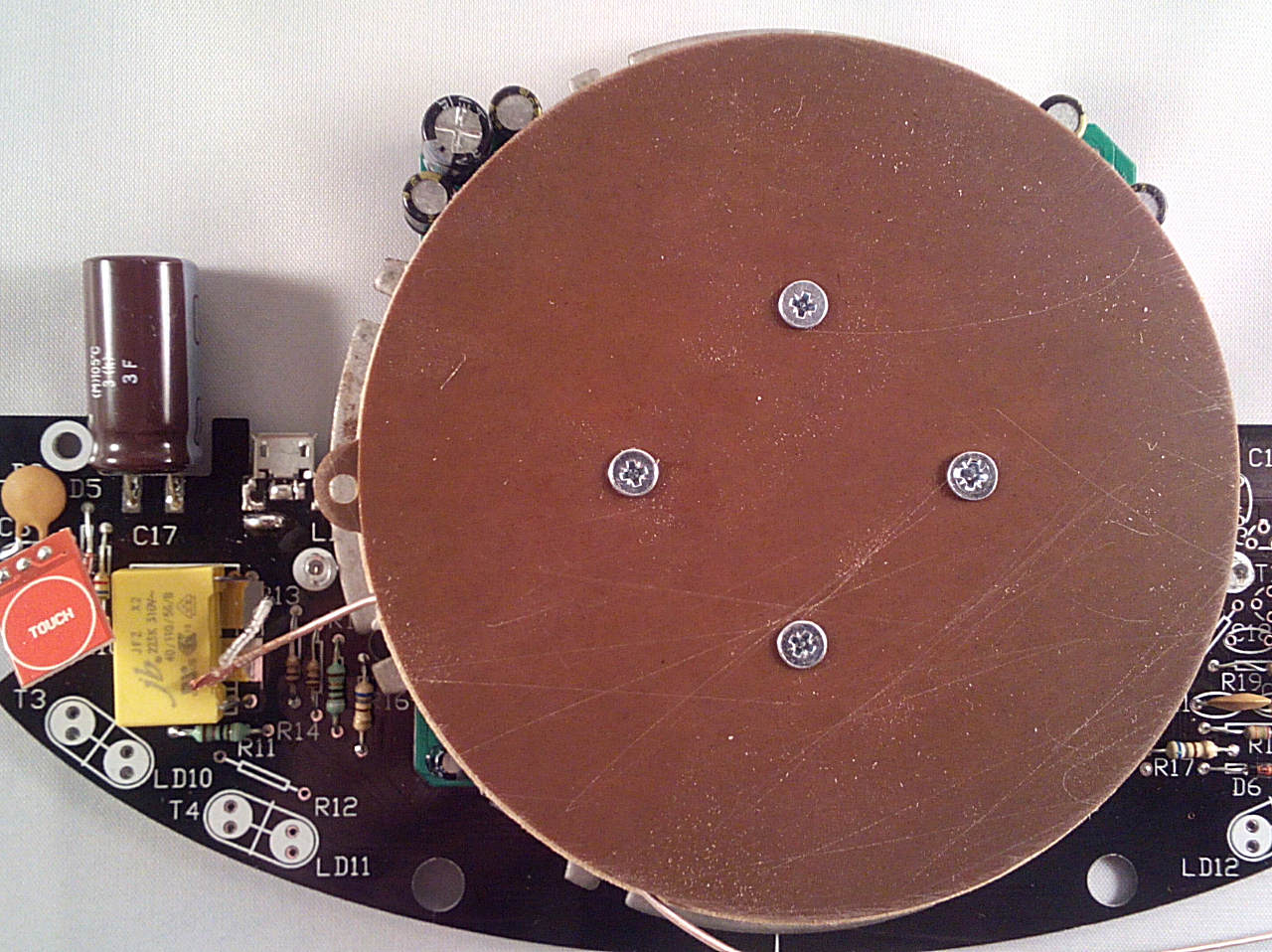

The coil former will need to be temporarily assembled on its own using 4x M3 bolts and nuts from the base fixings pack to fix the 3 paxolin pieces together, the coil can then be wound and sealed with superglue or similar. Once set remove the temporary bolts and glue the MDF spacer and coil to the magnet base.