If you received this version please go to the 'Board PCB - Red version' thread.

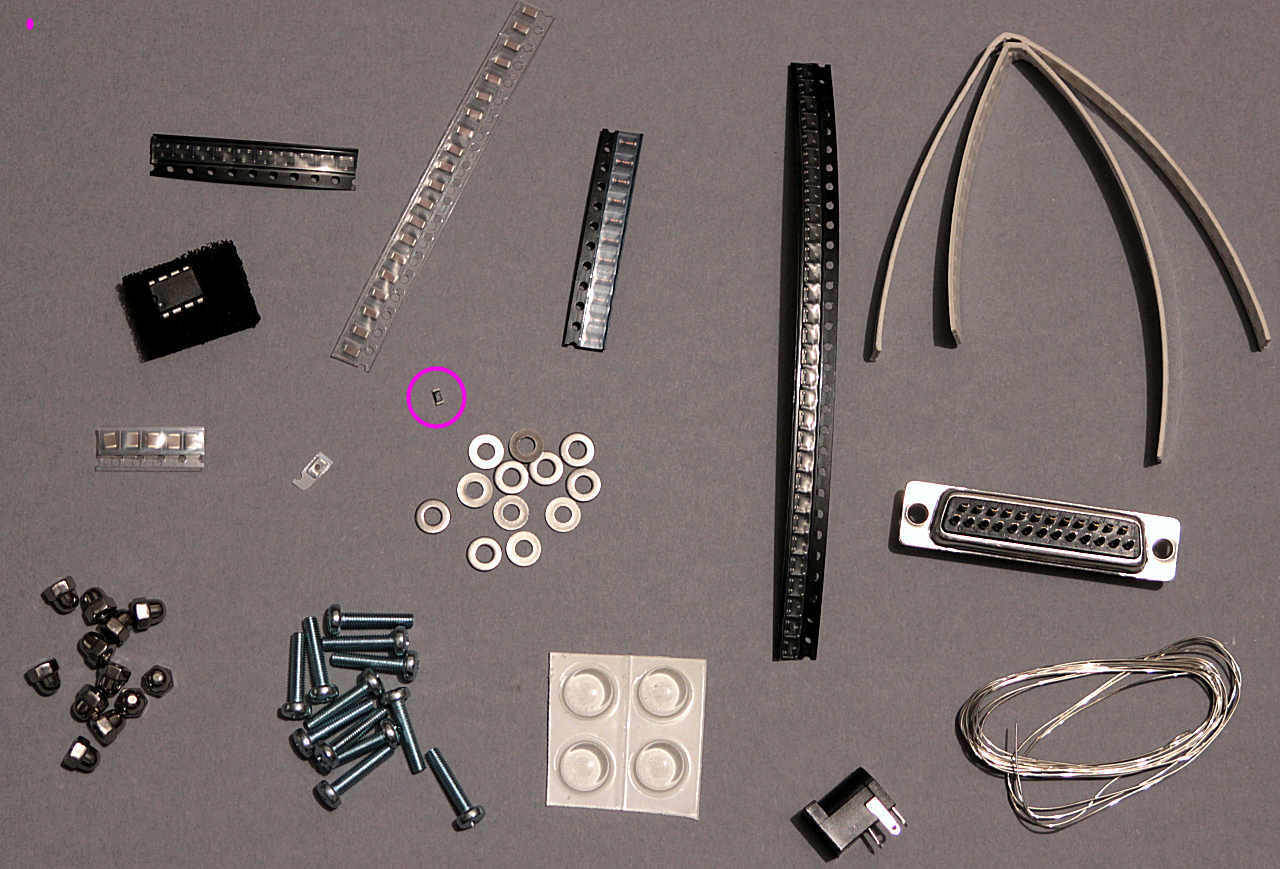

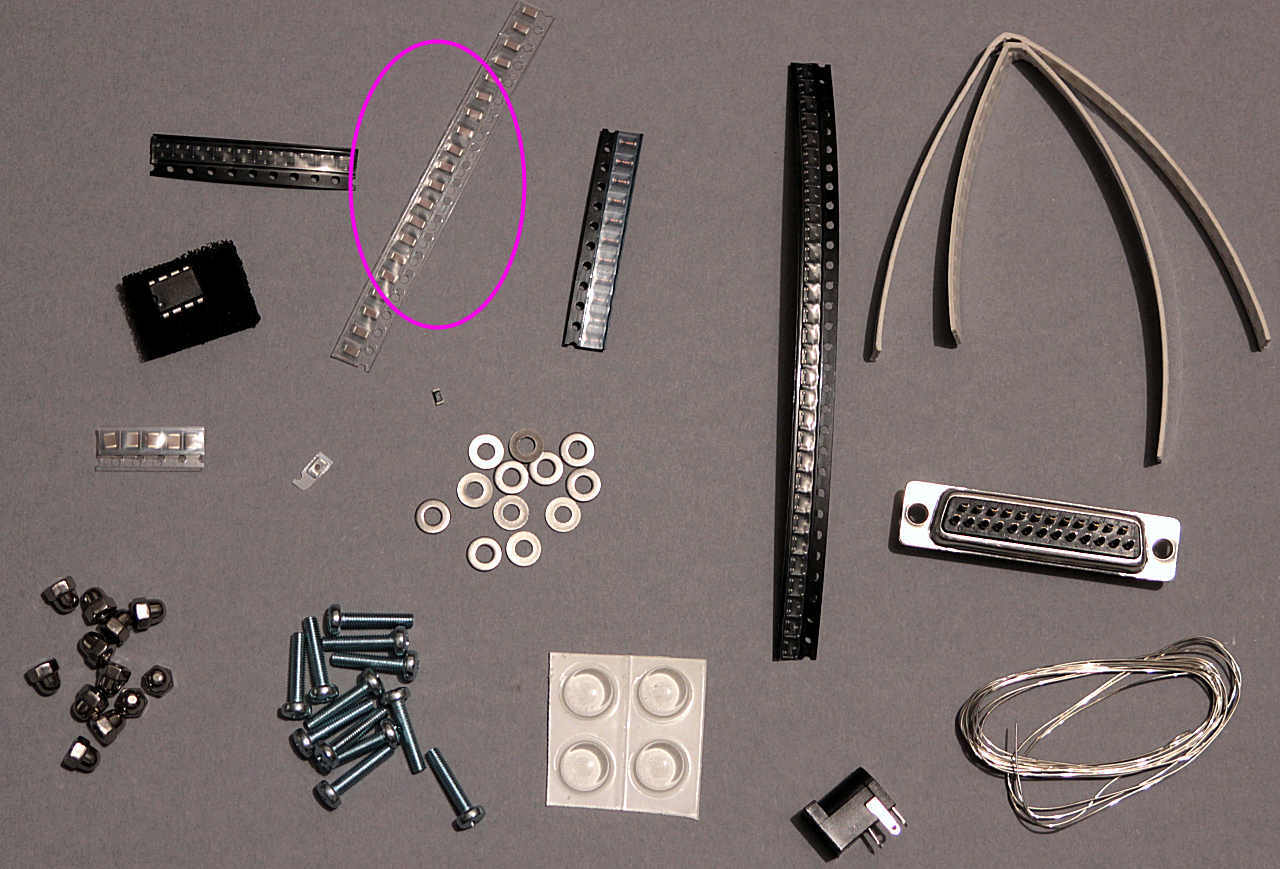

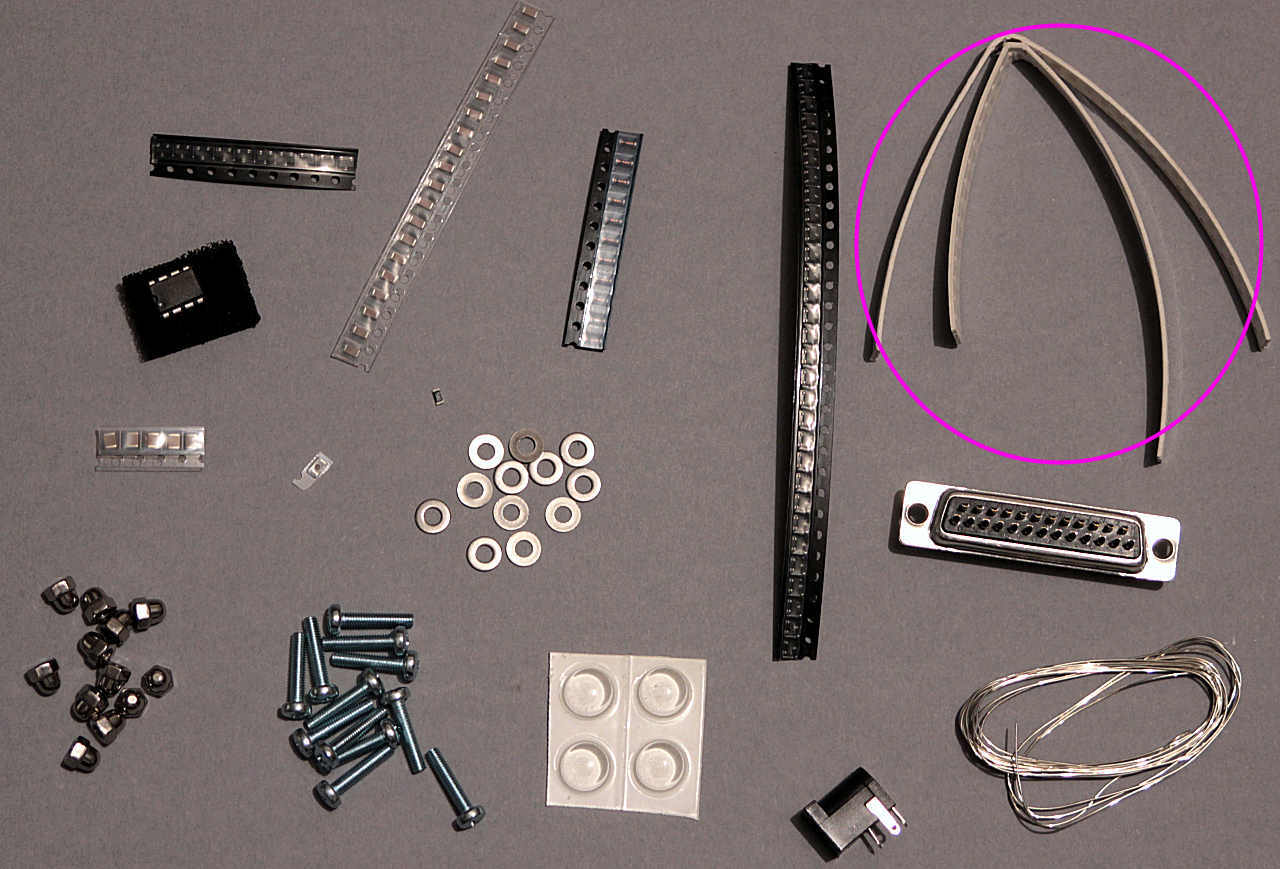

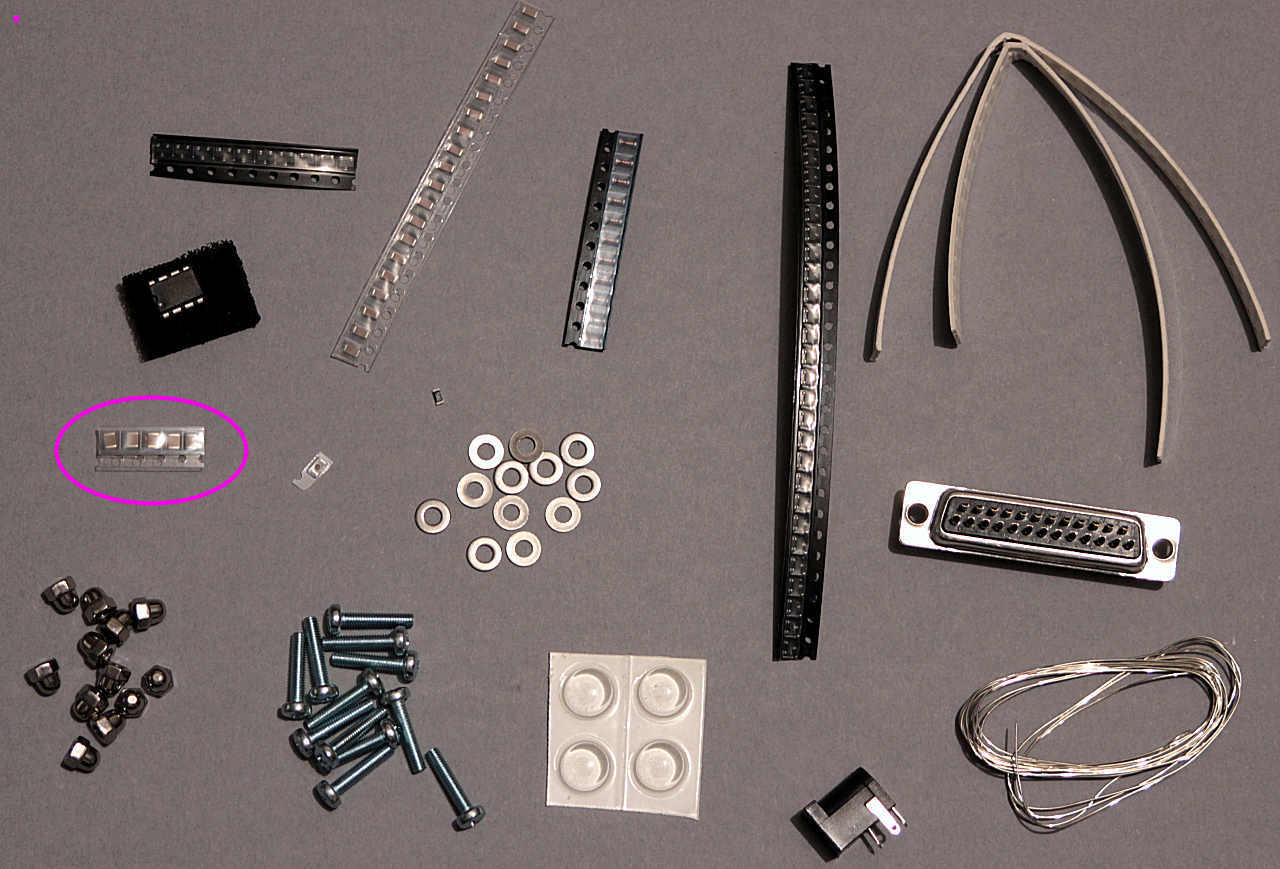

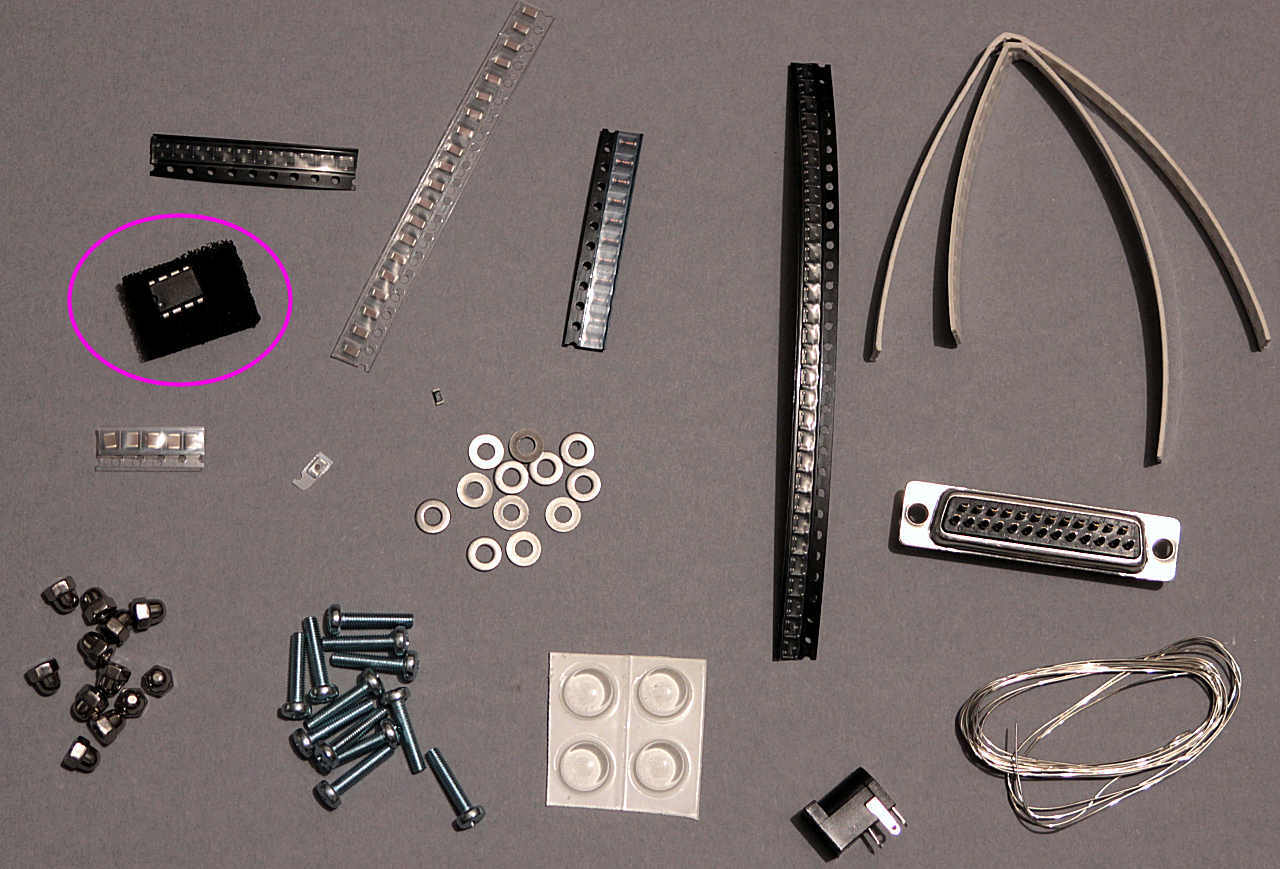

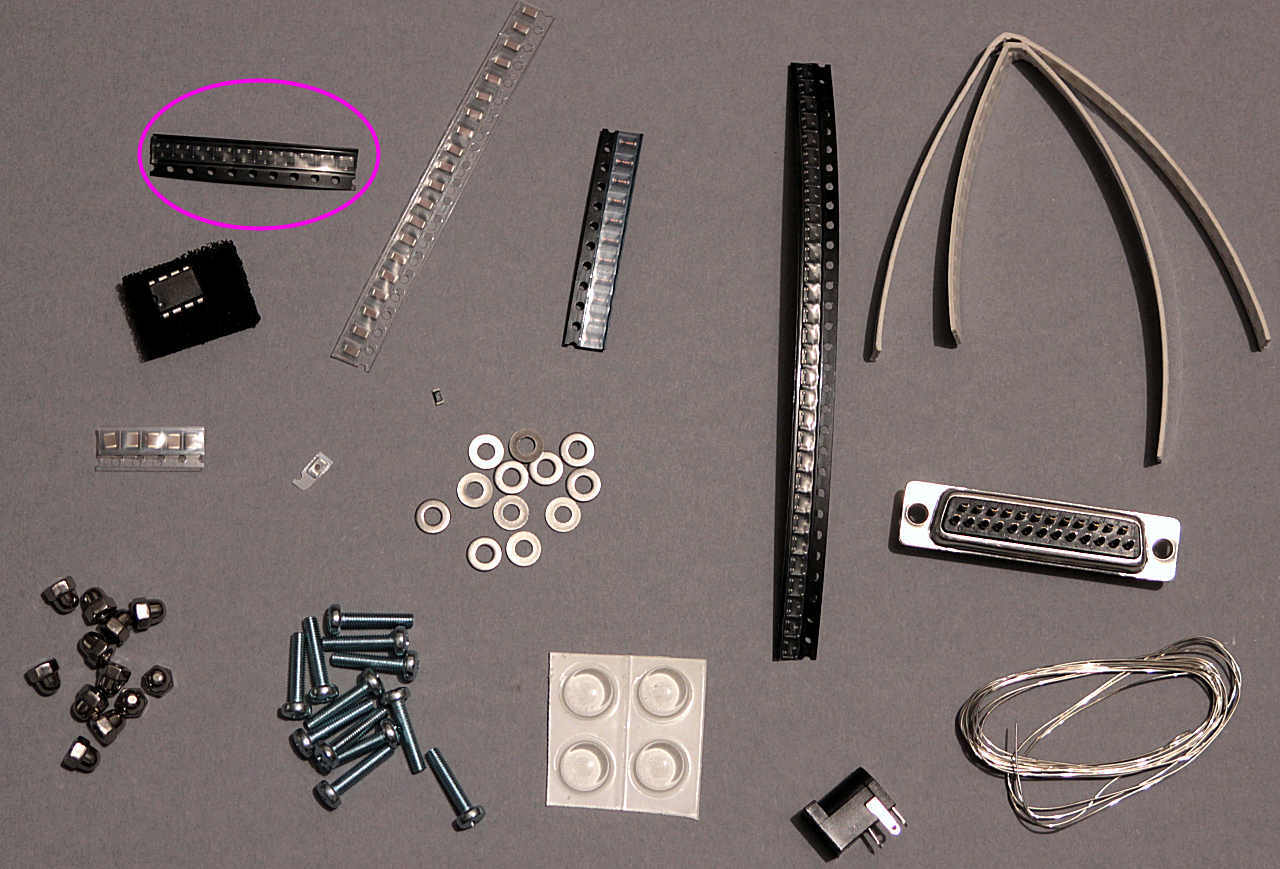

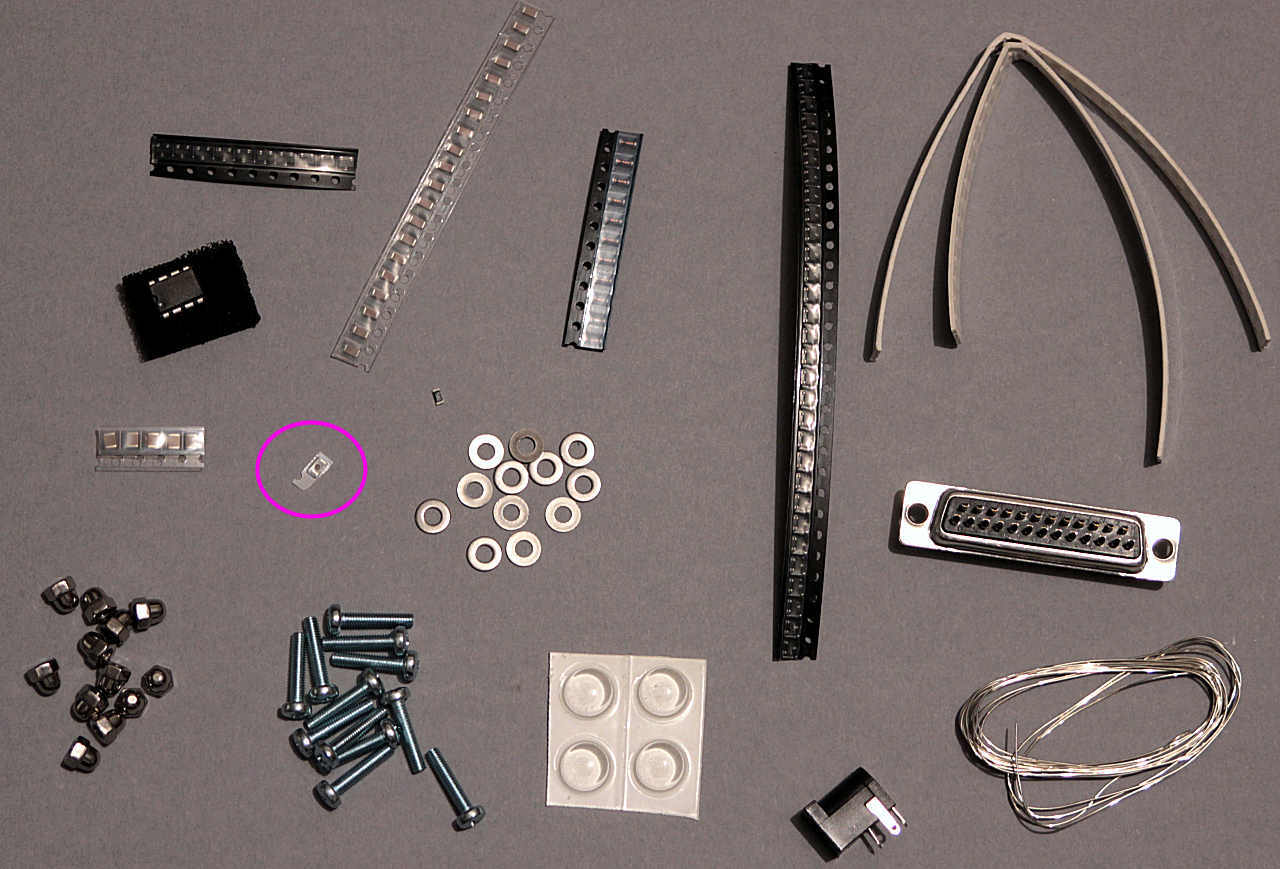

Unpack the component bag and sort them out into separate piles. You should have:

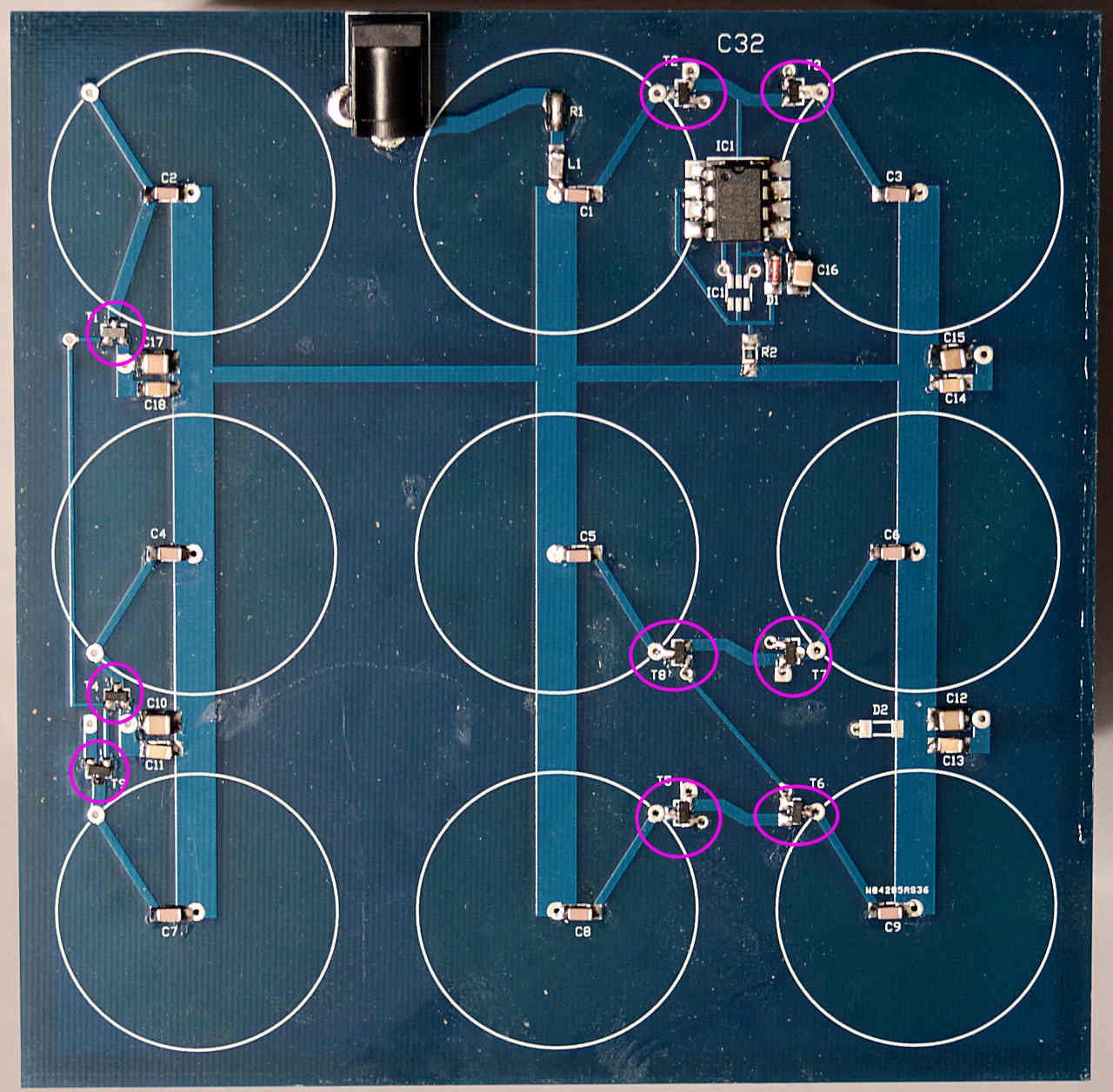

9x 2n7002 transistors (3 legged rectangles) These must be fitted the right way round.

18x 1n ceramic capacitors (grey ceramic)

9x BAV99 diodes (glass beads)

27x BAV103 diodes (3 legged rectangles, don't mix them up with the transistors) These must be fitted the right way round.

70x 100n capacitors (brown ceramic)

5x 10u capacitors (large brown ceramic)

1x 100R resistor (black rectangle with printed white number) - not in the latest batch.

1x 25 way D socket, for tube pins

12x M3x16 bolts, M3 washers and M3 dome nuts for case assembly.

4x rubber feet

5g solder

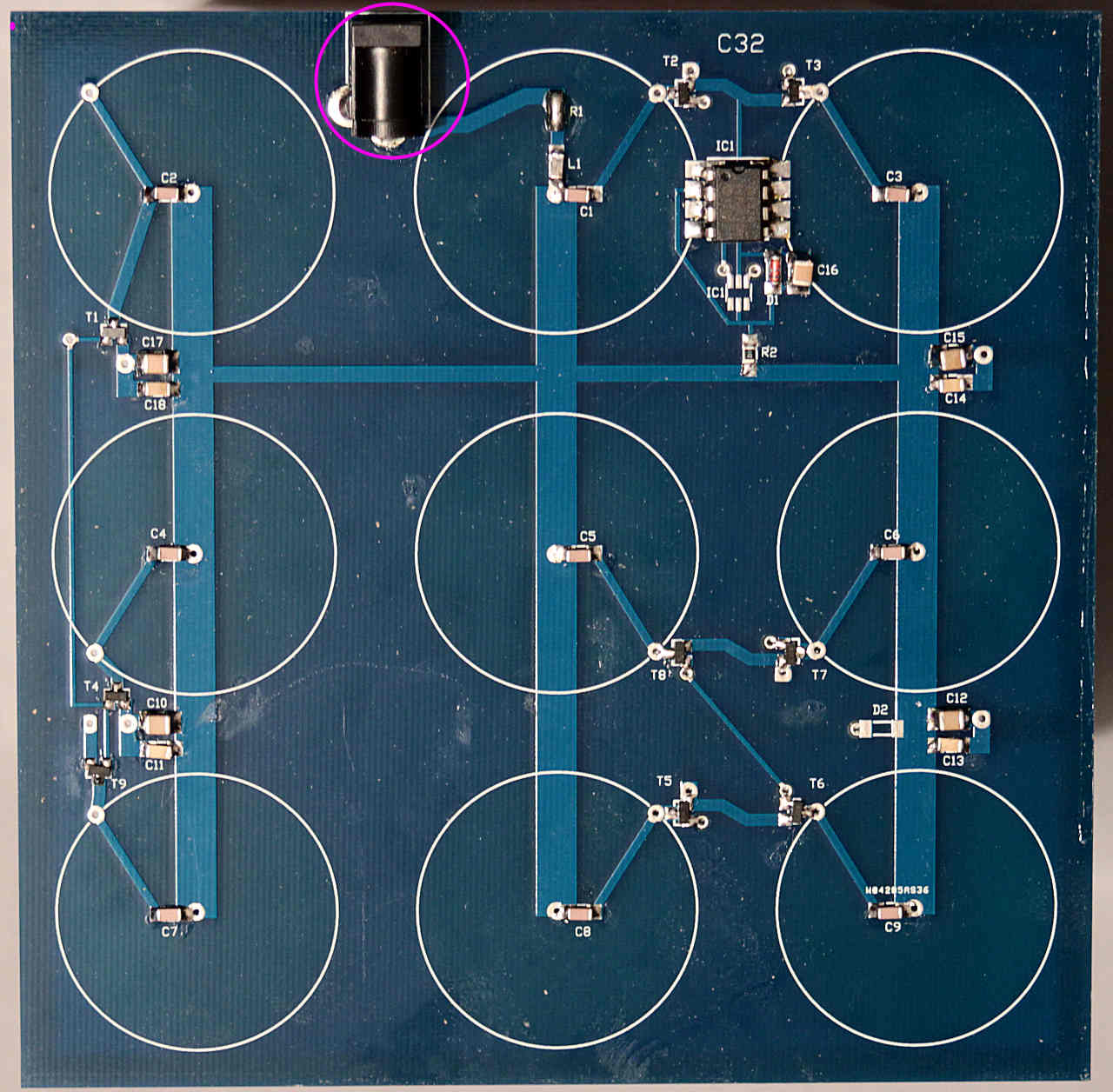

1x 3.1mm socket

Only some of these are needed here, most are used for the display piece PCBs and the hardware for the case.

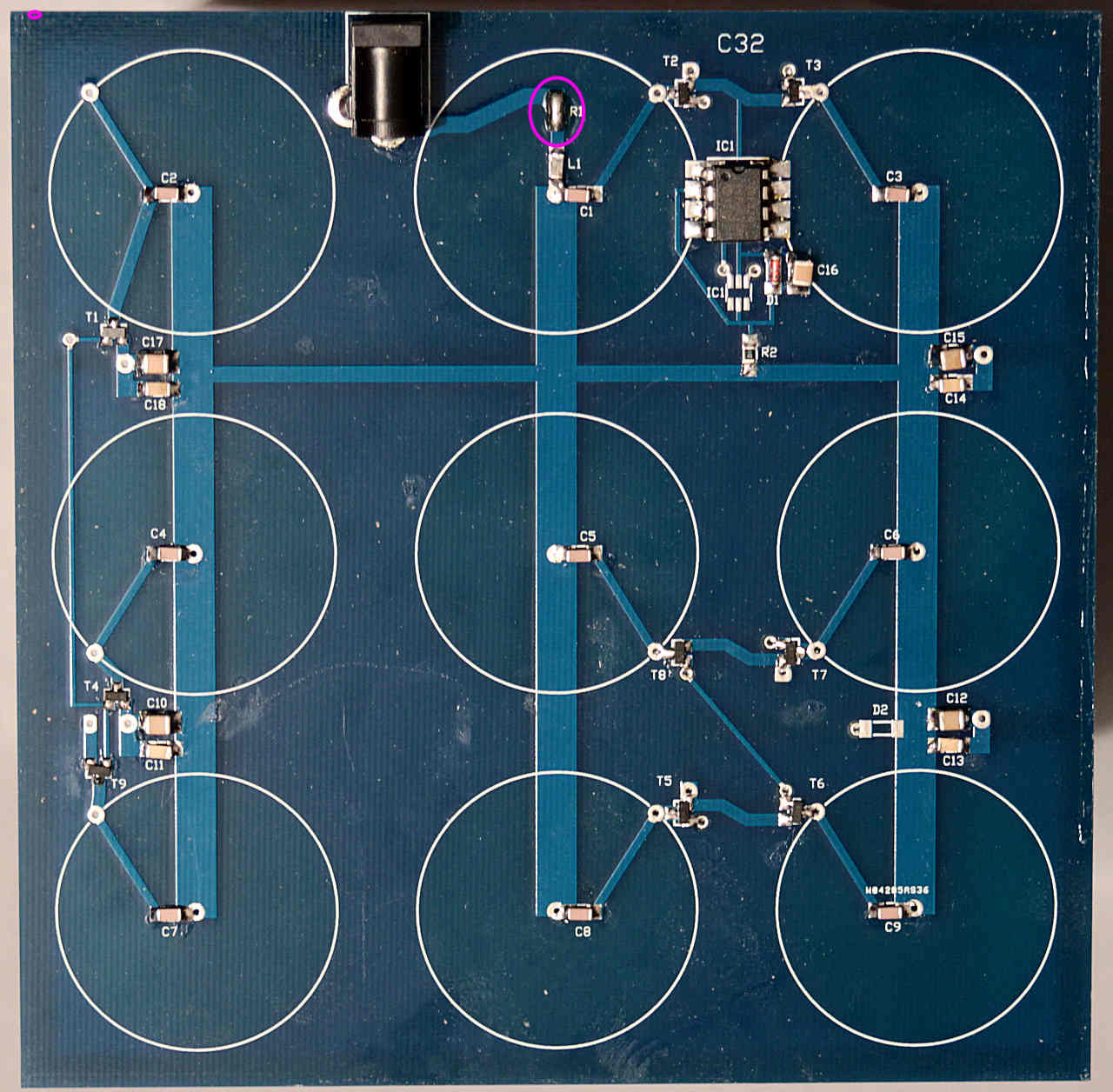

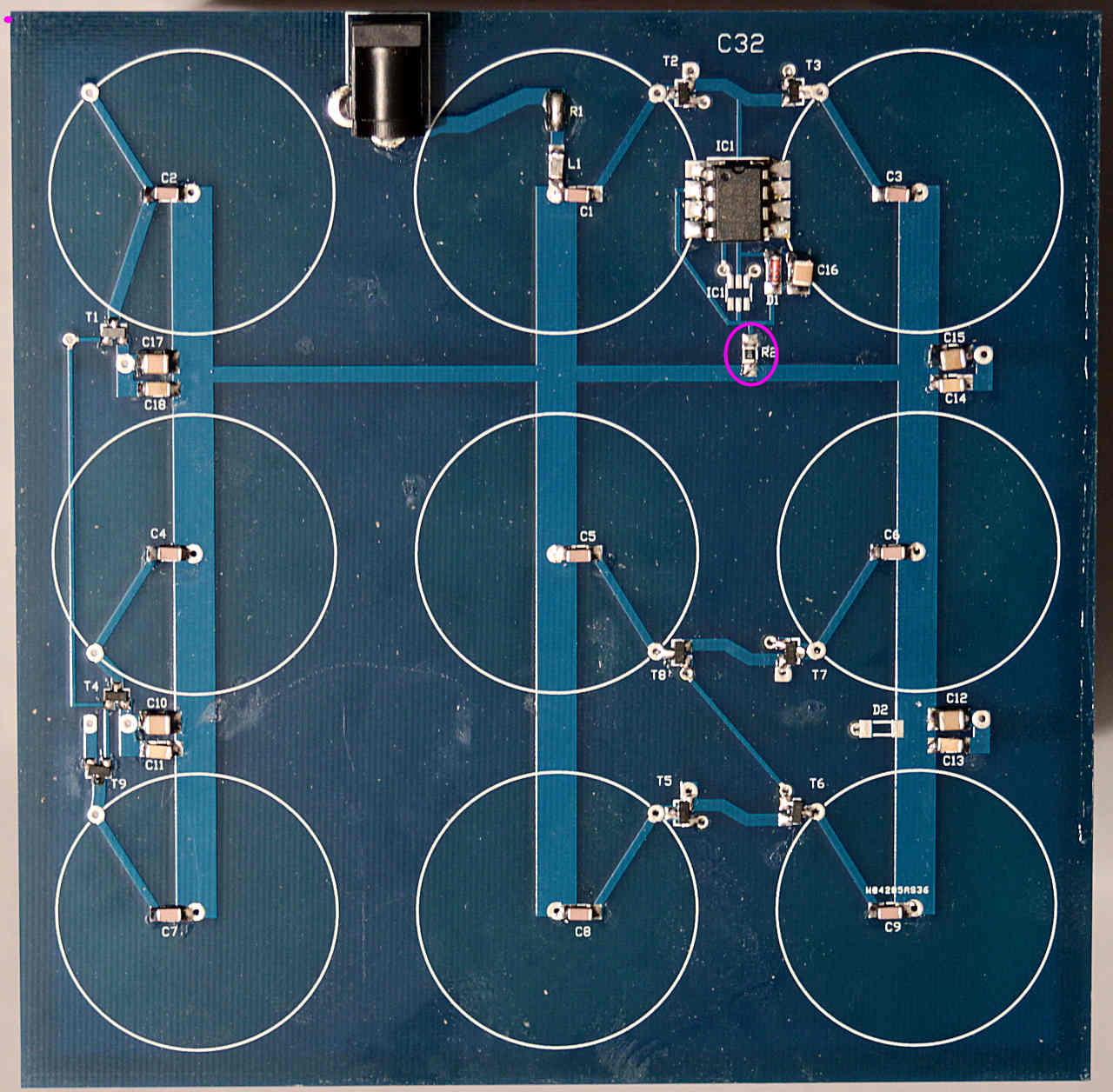

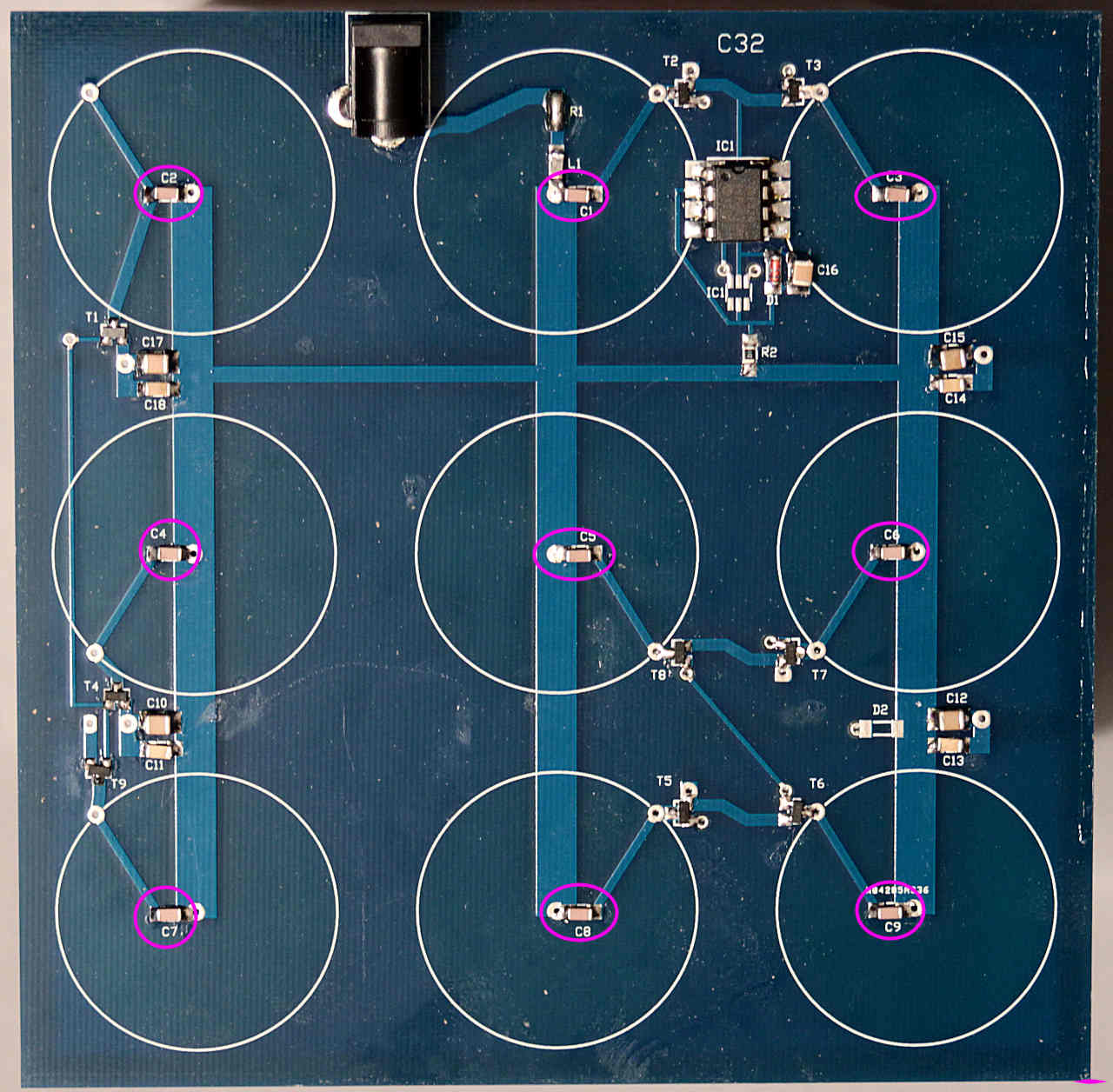

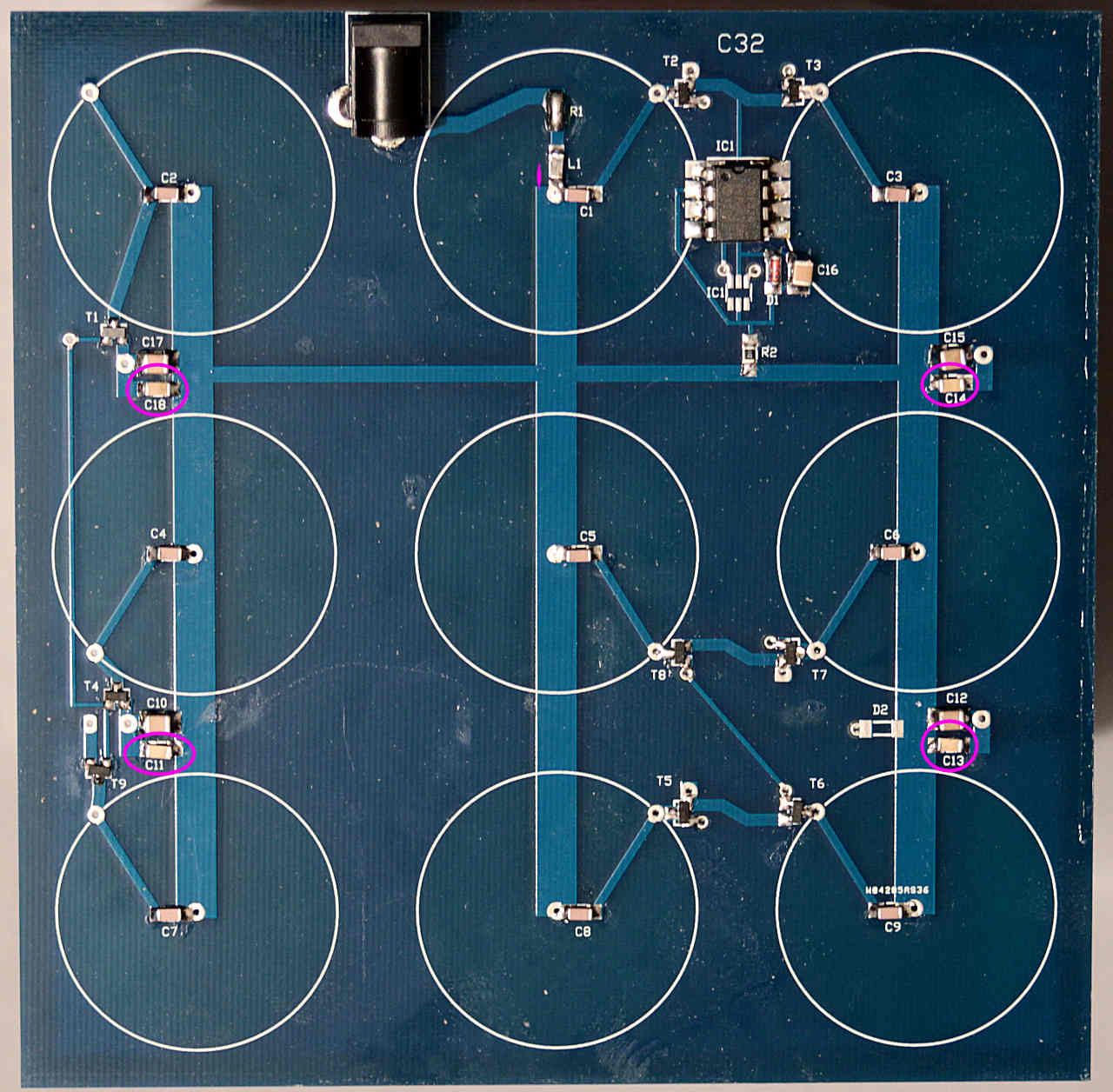

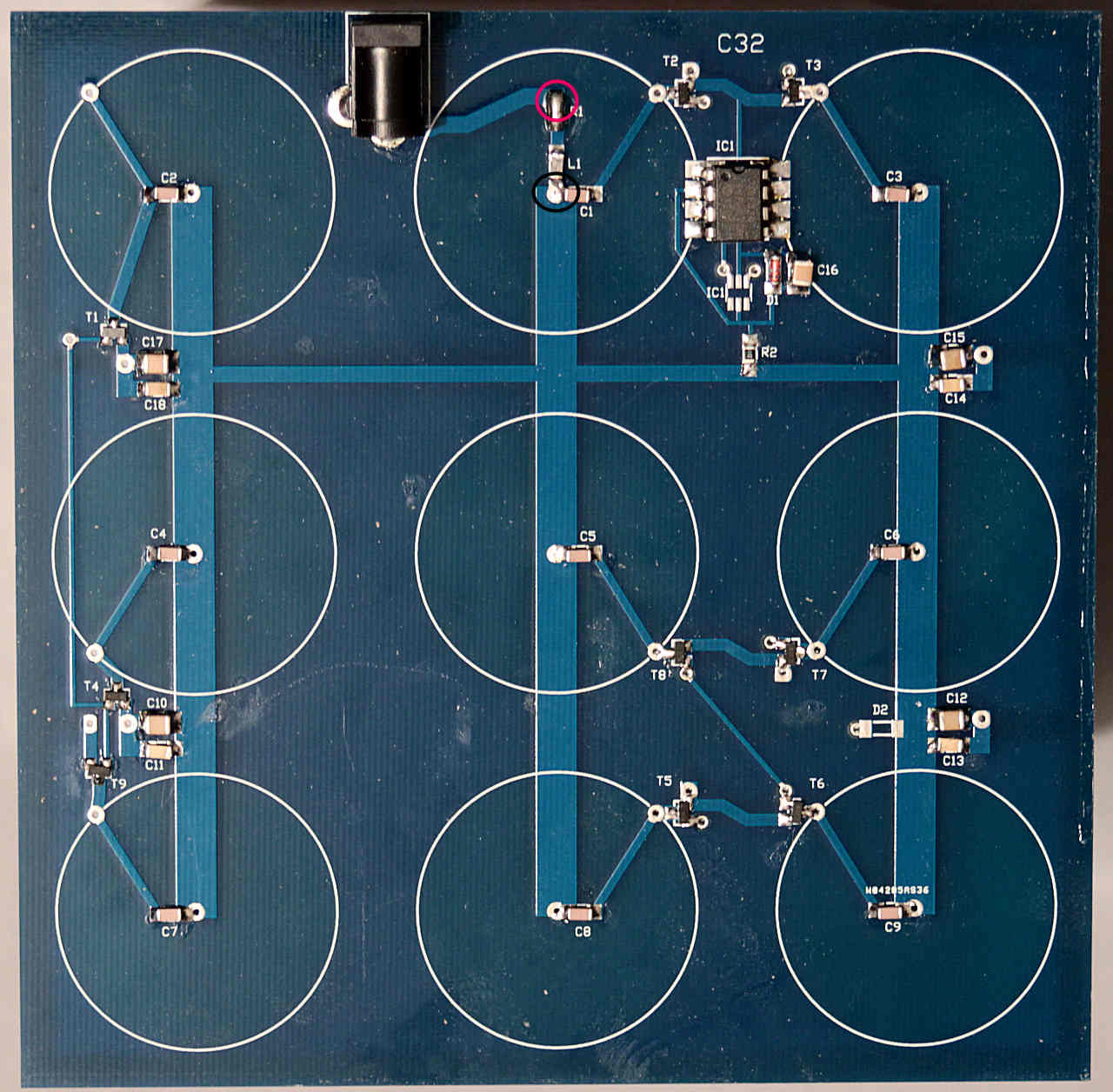

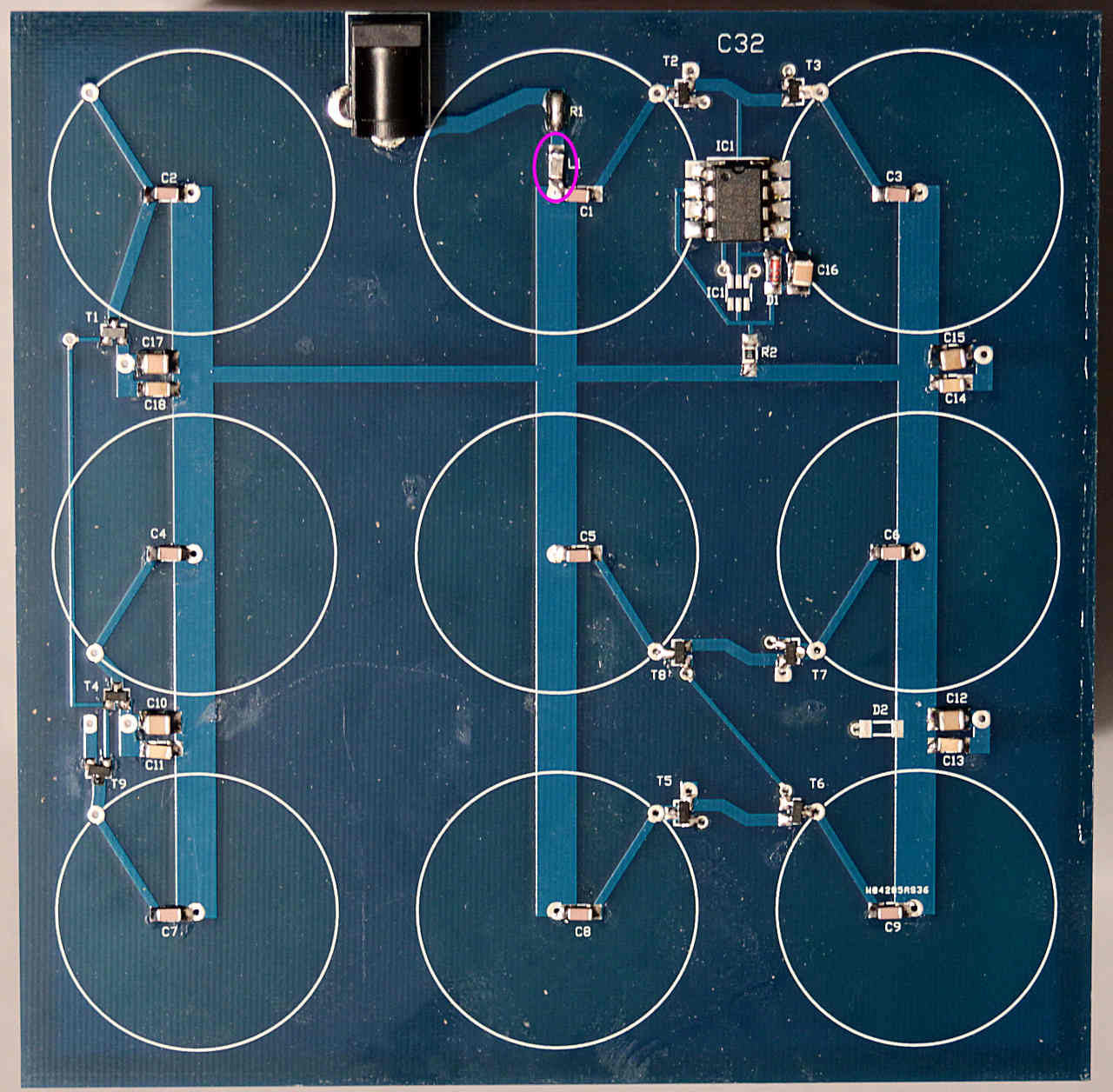

Start by bridging the pads for R1