It's now time for the final power up testing, with the coil drivers running with a 12V supply one at a time. You'll need a few completed piece PCBs with nixies fitted at this point as well.

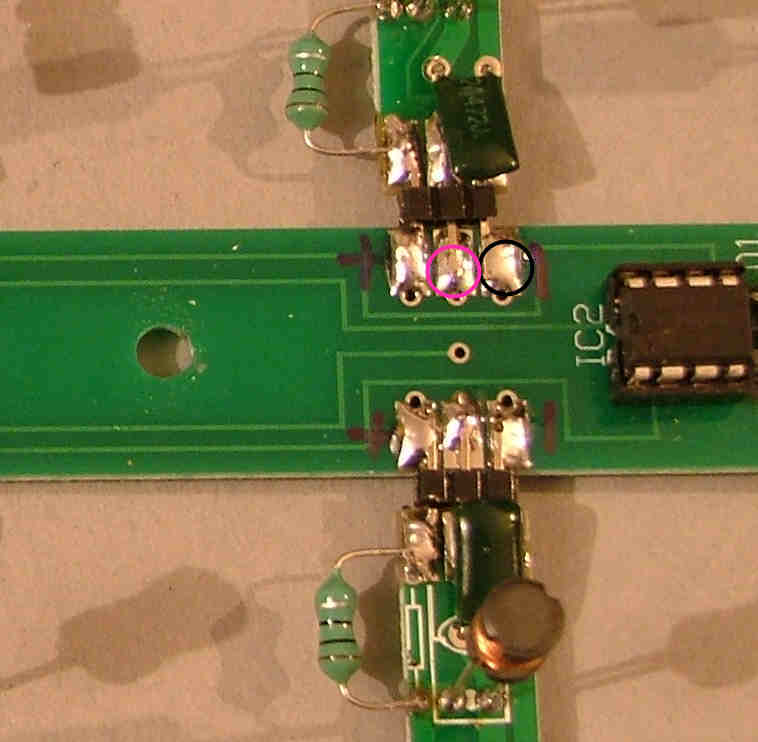

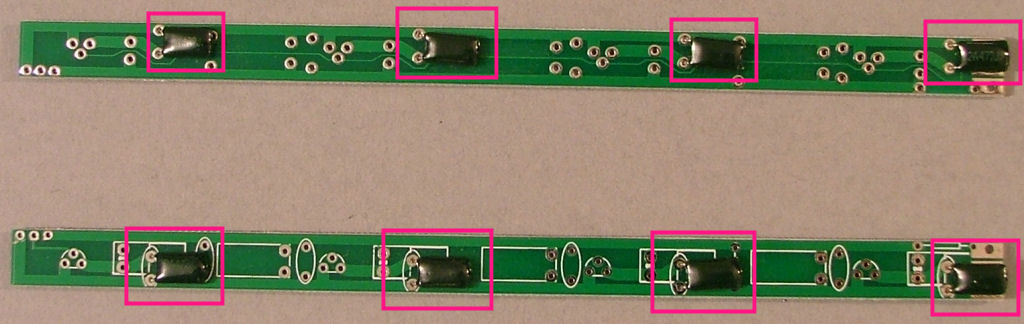

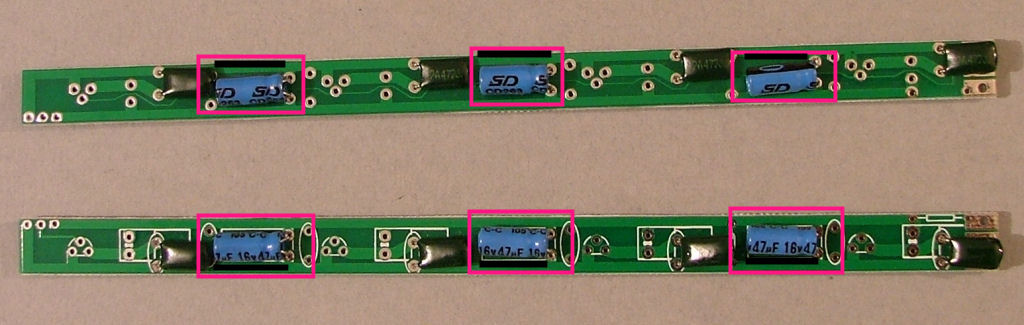

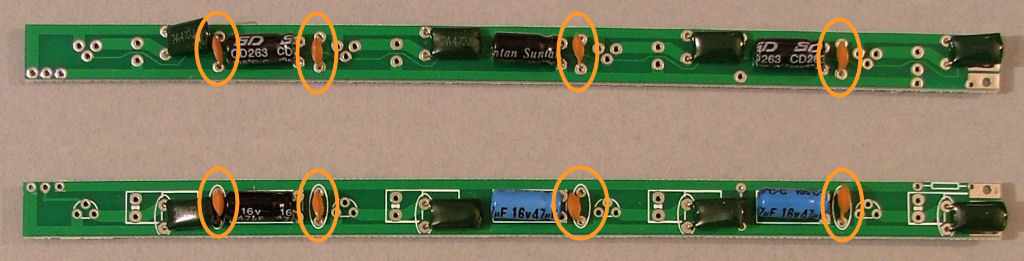

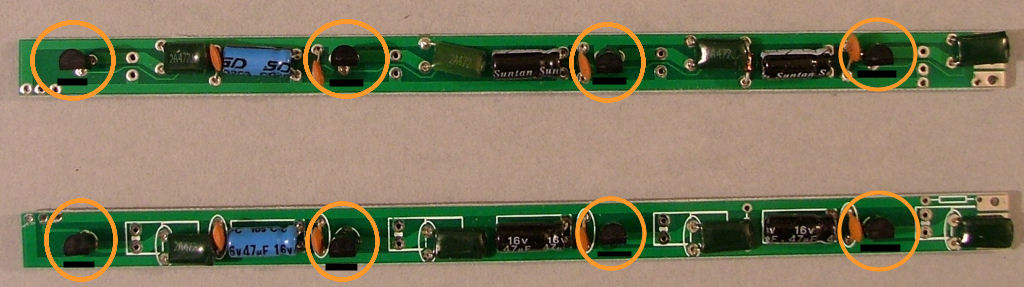

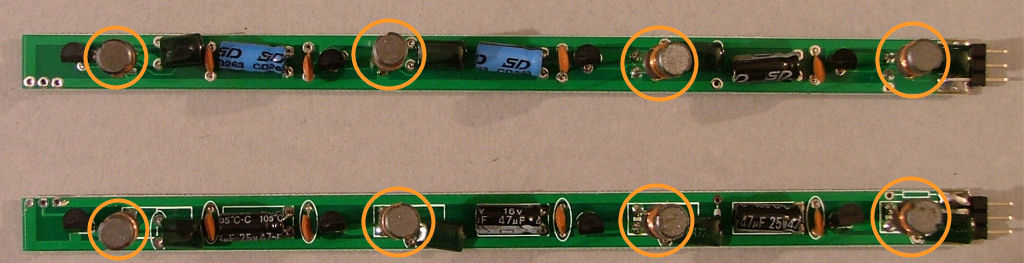

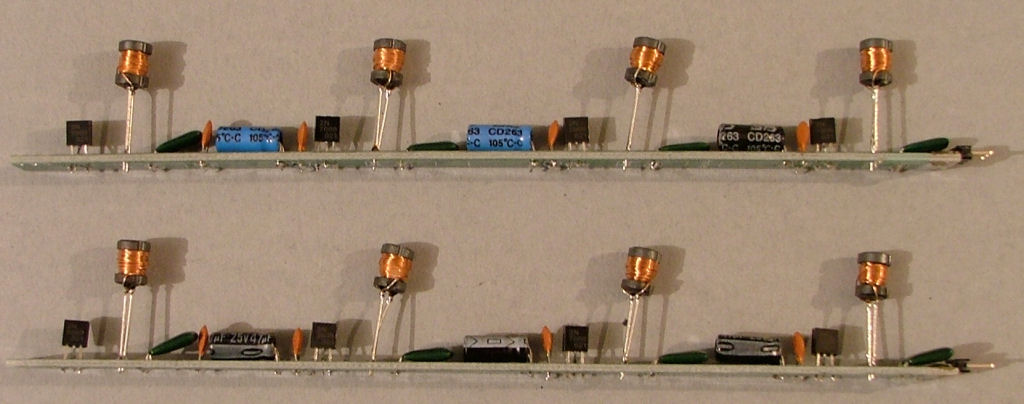

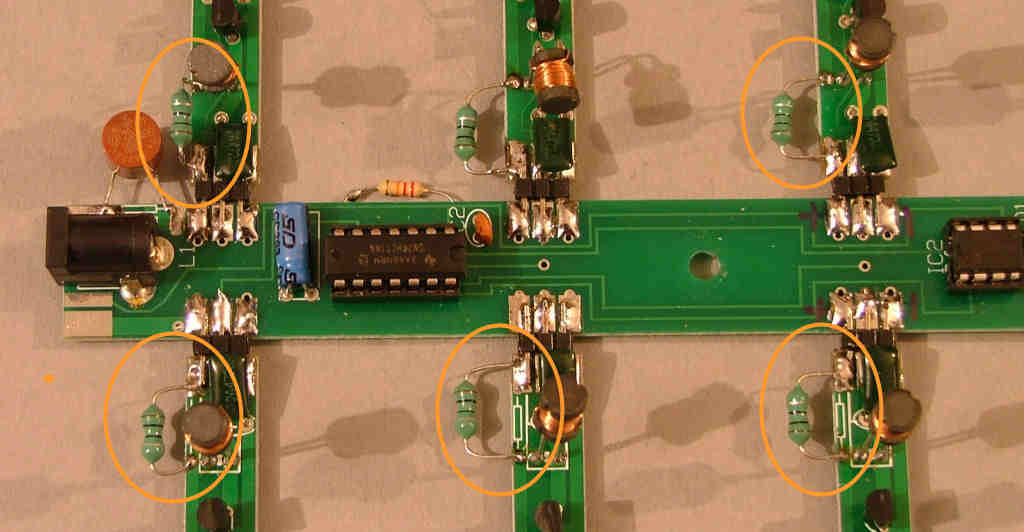

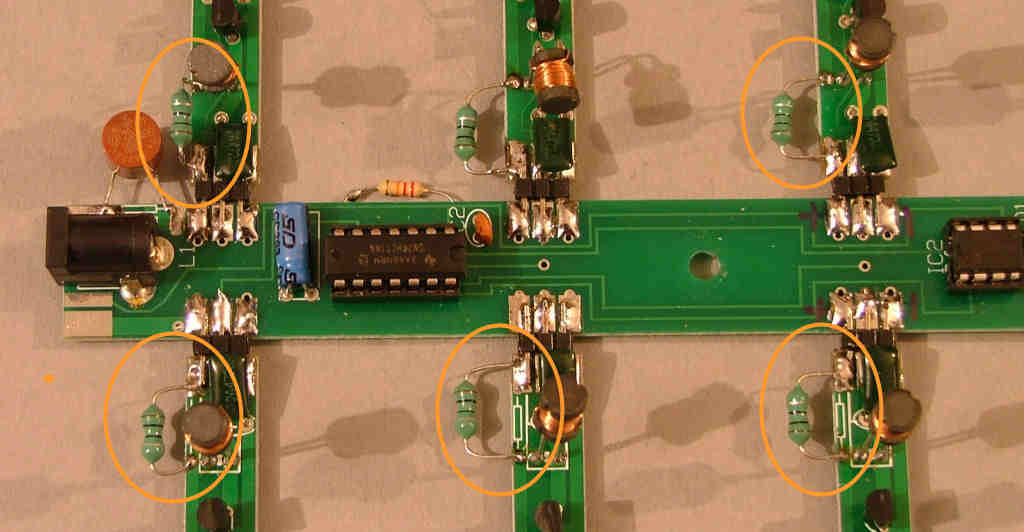

Temporarily tag one of the chokes (green resistor-like component) across the L1 pads on the first coil PCB (the order isn't important). The photograph shows a number of them fitted but for now just connect ONE at a time.

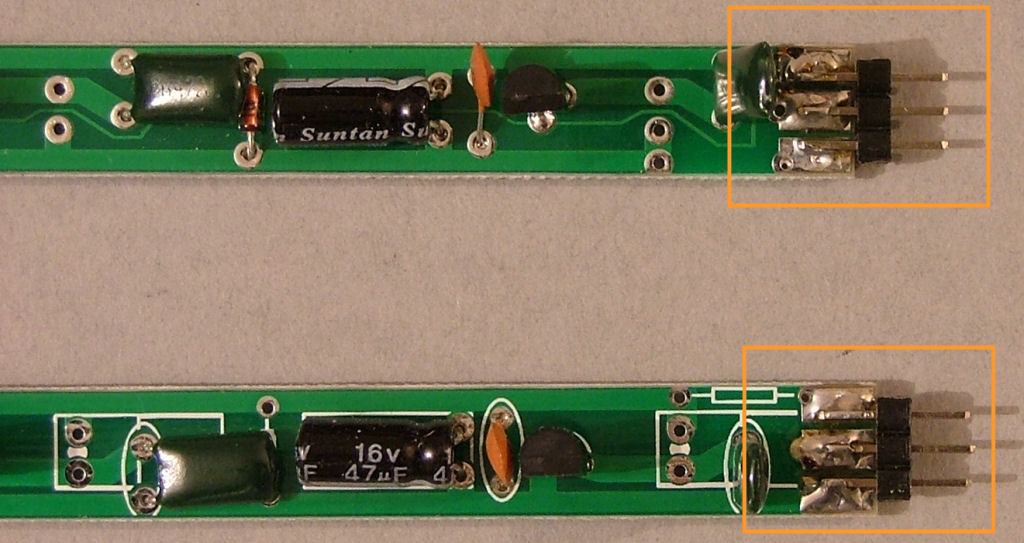

Connect your meter on a mA range that will display up to 250mA to the F1 pads and switch on. You should have a reading of 70-85mA, if it's higher than 100mA switch of quickly and check for shorts under that coil PCB.

If the current reading is OK hold one of the completed piece PCBs with its pickup coil near one of the four powered coils, its nixie should light up. If not try another piece PCB in case there's a fault with that piece.

Once you've confirmed it's working switch off, remove the choke from that PCB, tag it onto the next and repeat the testing process for the next 15. Don't leave a working PCB's L1 connected up once tested as it could be damaged if the next one you try has a fault.

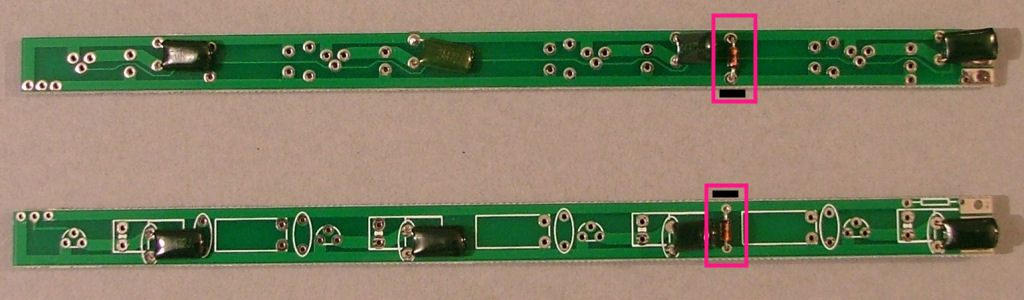

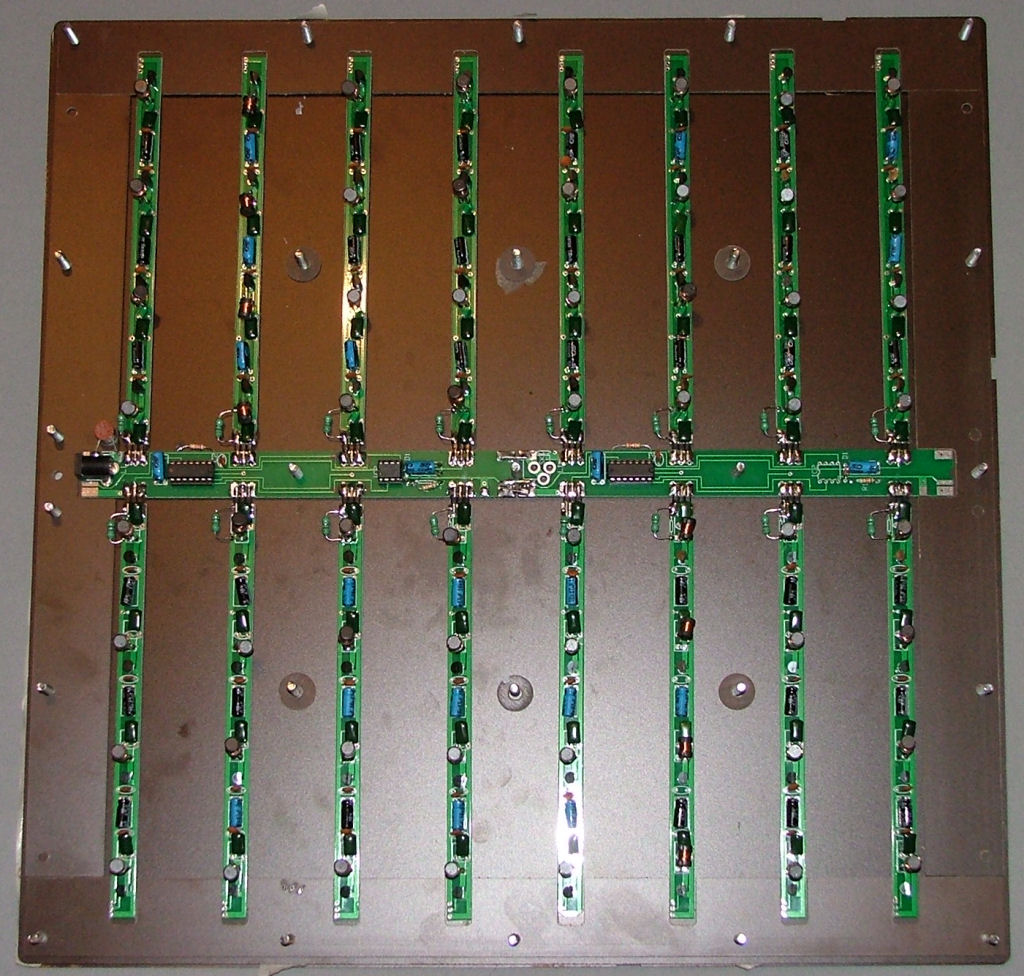

After all 16 have been tested and are working fit chokes on the first 4 boards L1 pads. Repeat the power on test with the mA meter set to a 2A or similar range. You should have a reading of about 300mA. Fit another 4 chokes to the next 4 boards and repeat, the reading should increase by about 300mA each time until you have all 16 connected and a reading of about 1.2Amps. At this stage remove the meter and fit F1.

The electrical assembly and testing is now complete and it's time for the fun job of bending each coil to exactly where the centre of each square will be. (Still less fun than winding 96 coils by hand

)

Whilst the small coil size of this design makes the coil position and piece placement more critical it does allow metallic items to be used near them, which was impossible with the older designs. The first modification I'm working on will be a wall-mounted vertical board with the pieces held in place using an array of magnets. Metal powder filled resin piece cases are also now possible for a real copper/brass/iron finish.