Page 1 of 1

Board case

Posted: Mon Nov 18, 2013 1:22 am

by Tony

Once the main PCB is completed and tested it can be built into the base case....

Gently brush the top panel engravings to remove any loose dust. You'll need to fill the engravings to make them legible, I used white acrylic fabric paint as it was handy - you could try other colours or materials.

Rub the paint into the engravings, making sure they're filled and there are no air bubbles:

Leave to dry then rub off the excess paint, taking care not to remove too much from the engravings.

Re: Board case

Posted: Mon Nov 18, 2013 1:27 am

by Tony

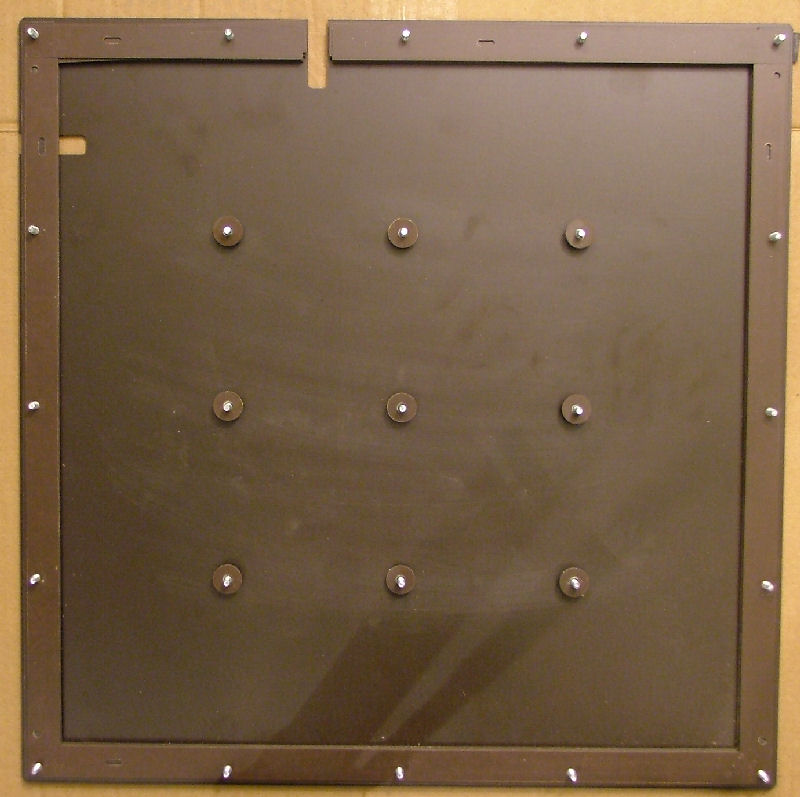

Take the 25x M4x20 bolts from bag1 and 25x M4 S/S washers. Note some kit variants will have 26 and/or brass instead of steel.

Turn the board so the cutout is facing right and in the lower half. Fit the bolts through a washer then through the holes in the base panel and hold in place with masking tape.

Now turn over the board and put one plain steel washer on each of the nine bolts in the centre, followed by two nuts on each bolt - these act as spacers for the PCB.

Re: Board case

Posted: Mon Nov 18, 2013 1:35 am

by Tony

Sort the pile of spacer strips into two lots - one with notches cut into them and one without. Starting with the shortest piece with a notch, fit it onto the corner as shown here:

Working anticlockwise now put down one longest notch piece, one slightly shorter notch and one more longest notch piece, finally completing the layer with a second-shortest notch piece.

For the next layer put down the shortest piece without a notch on top of the first piece fitted last time followed by one second longest no-notch piece, one longest no-notch and one more second longest no-notch piece, finally completing the second layer with a second-shortest no-notch piece. After completing 5 alternating layers it should look like the above picture.

It's a lot easier to do than to explain.

Re: Board case

Posted: Mon Nov 18, 2013 1:39 am

by Tony

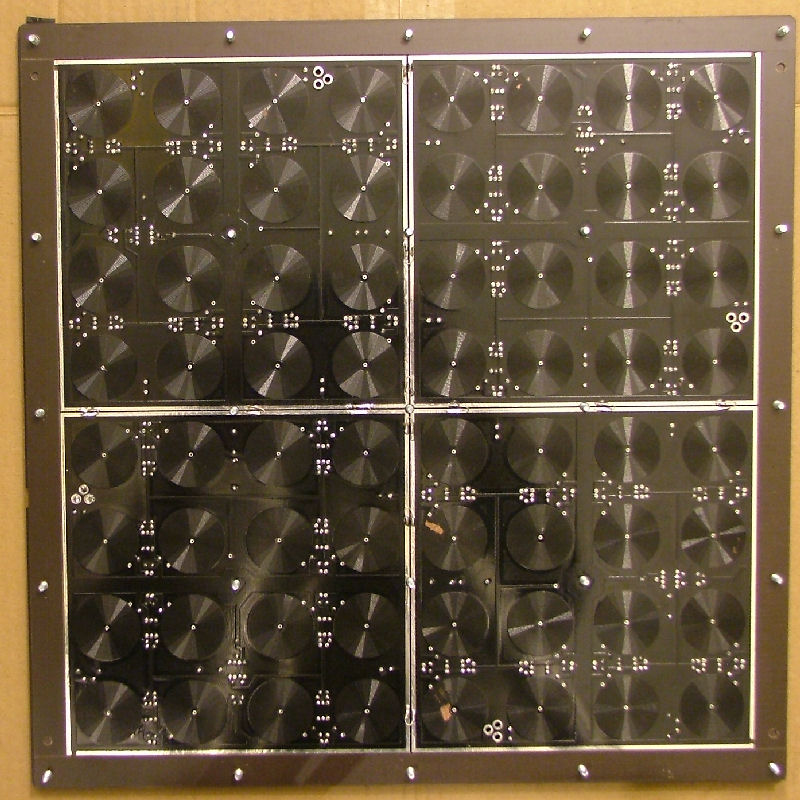

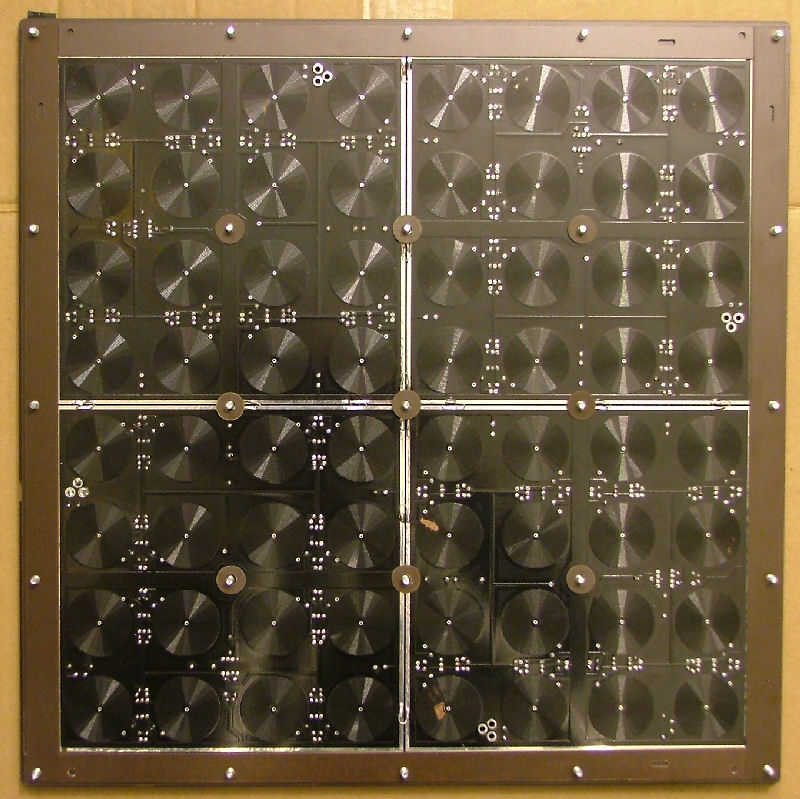

Now put a paxolin spacer on each of the 9 bolts in the centre of the board. Lower the complete PCB assembly with the components facing down into the case.

Now place the last layer of strips with notches oarund the edge to hold in the PCB.

Put another paxolin spacer on each of the 9 bolts in the centre of the board to support the board top.

It's now ready for you to put the finished engraved bord on, make sure the '12V power' engraving lines up with the socket. Bolt into place with the reamining 25 stainless steel washers and 25 dome nuts.